Executive Summary

SunnyVale Dairy Farms, LLC is a new dairy farm in Okeechobee, Florida, at 1842 County Road 42. The farm will produce fresh milk, cream, and butter using modern machines and eco-friendly methods.

We are a mid-sized, family-run dairy with around 180 to 240 cows. This plan is created to help secure USDA-backed funding to build, equip, and grow the farm. It also outlines how we’ll operate safely, care for our cows, protect the environment, and build a steady income over time. The goal is to create a clean, efficient, and trusted local dairy that supports both the community and the region’s milk supply.

Market Opportunity

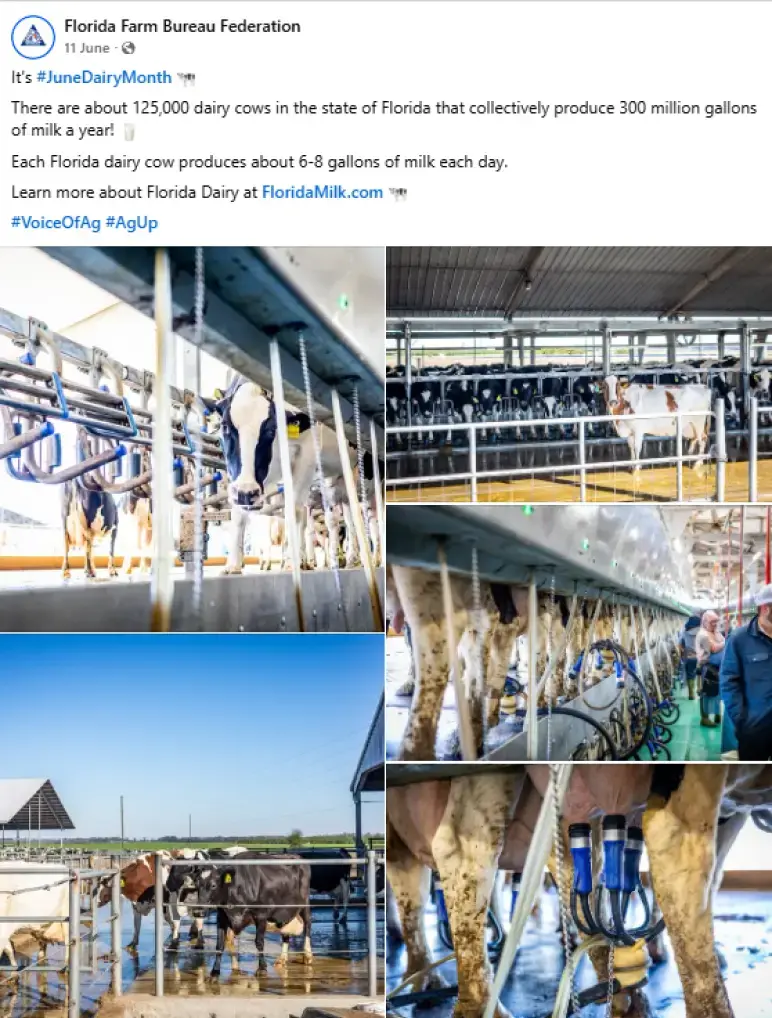

Florida has about 125,000 dairy cows, producing around 300 million gallons of milk each year. There is still room to meet local demand, making Okeechobee County a good place to grow.

Increasing consumer interest in locally sourced and sustainable dairy products opens clear opportunities for SunnyVale’s “farm-to-fridge” approach. The farm will focus on supplying regional processors and schools in the first two years, before launching its own branded retail line by Year 3.

Target Market

SunnyVale will primarily serve:

- Milk processors like Lactalis USA and Borden Dairy.

- Institutional buyers like Florida school districts and local food programs.

- Regional retailers and direct consumers through branded milk and yogurt lines starting in Year 3.

This mix keeps income steady while building the brand in Orlando and West Palm Beach.

Ownership

SunnyVale Dairy Farms is owned and operated by David and Melissa Whitmore, a husband-and-wife team with a mix of farming expertise and business experience.

David Whitmore (70%) is a third-generation dairy farmer with over 15 years of experience. He worked as Operations Manager at Larson Dairy, Florida’s largest milk producer.

Melissa Whitmore (30%) has an MBA in Agribusiness from the University of Florida and worked in farm finance. She manages the farm’s accounts and operations.

Together, they bring strong farming knowledge and smart business management.

Financial Outlook

SunnyVale will start with 180 cows, making about 462,000 gallons of milk in the first year and growing to 590,000 gallons by Year 3.

In the first year, the farm should earn around $947,100 while getting started. In Year 2, income is expected to rise to about $1,128,750 as the herd grows and sales increase. By Year 3, revenue could reach $1,327,500 with full production and the new SunnyVale brand.

| Financial Year | Herd Size | Milk Output (gal) | Revenue |

|---|---|---|---|

| Year 1 | 180 | 462,000 | $947,100 |

| Year 2 | 210 | 525,000 | $1,128,750 |

| Year 3 | 240 | 590,000 | $1,327,500 |

The farm expects to start making a profit in Year 2, with about 8% net profit by Year 3, and loan payments will be easily covered.

Funding Requirement

SunnyVale is asking for a $950,000 USDA-backed loan through AgAmerica Lending, supported by the USDA Farm Service Agency (FSA). The loan will be for 15 years at a 5.5% fixed rate. The owners will invest $280,000 of their own funds, bringing total funding to $1.23 million.

Spending days structuring a business plan?

Let Upmetrics AI handle the first draft so you can focus on details

Business Overview

Legal Structure

SunnyVale Dairy Farms, LLC is a family-owned dairy business in Okeechobee, Florida, located at 1842 County Road 42. The company will be formed in January 2026 as a Florida Limited Liability Company (LLC) and is registered with the Florida Department of State. The LLC setup gives the business legal protection, tax benefits, and keeps it family-managed.

The farm is based on a 120-acre property and will start operations once it receives its Florida Milk Producer License, USDA Grade “A” Dairy Permit, and EPA Livestock Wastewater Certification.

Mission Statement

To produce fresh, high-quality milk and dairy products in a safe, clean, and sustainable way, caring for animals, the environment, and the local community.

Vision Statement

To become one of Florida’s most trusted and sustainable dairy farms, known for great quality, responsible farming, and community values.

Ownership & Management

| Owner | Ownership % | Title | Primary Responsibilities |

|---|---|---|---|

| David Whitmore | 70% | Managing Member / Farm Operations Director | Handles herd care, daily operations, equipment, and supplier management |

| Melissa Whitmore | 30% | Managing Member / Finance & Compliance Director | Manages finance, payroll, records, and lender communication |

David is a third-generation dairy farmer in Florida with over 15 years of experience. He used to work as Operations Manager at Larson Dairy Inc., the state’s largest dairy, where he managed 1,000 cows and 25 workers. He knows a lot about cow health, feed planning, and farm technology. At SunnyVale, he will run daily farm operations and handle suppliers.

Melissa has an MBA in Agribusiness from the University of Florida and worked as a Loan Analyst at SunTrust Bank, focusing on farm loans and USDA programs. At SunnyVale, she will manage finances, payroll, and regulations, keeping the farm’s books in order and helping with smart business planning.

Both owners are personally guaranteeing the USDA-backed loan to show full commitment to the project.

Land and Property Details

SunnyVale Dairy Farms operates on 120 acres of farmland, which includes both owned and leased land for rotational grazing. The property includes:

- Four dairy barns, one currently being renovated with solar integration

- Two feed silos with 12,000-bushel capacity

- A new manure lagoon and methane digester pad

- Two equipment sheds and a milk storage building with an 8,000-gallon bulk tank

The land is zoned for agriculture, has well and power connections, and is fully insured. All facilities will be appraised as part of the loan process.

Advisory & Support Resources

SunnyVale will work with trusted partners to help the farm run well. BioTek Solutions will take care of the cows’ health and regular checkups. Cargill Feed & Nutrition will provide animal feed under a three-year fixed-price deal. The farm will use modern milking machines from DeLaval North America, including the VMS V300 robotic system. A certified agricultural CPA will handle the farm’s accounting and USDA/FSA financial reports to ensure compliance and accuracy.

Business Goals

SunnyVale Dairy Farms wants to grow slowly and safely in the next few years while staying focused on good quality, animal care, and the environment. The main goals are:

- Grow the herd to around 400 cows in the next five years.

- Build a small plant on the farm to make and pack milk, cheese, and yogurt.

- Sell SunnyVale-branded products in local stores across Florida.

- Use only clean energy like solar and biogas by 2030.

- Create more local jobs and give training to young people.

- Keep strong animal care standards and use eco-friendly methods.

These goals will help SunnyVale become a modern, green, and community-friendly dairy farm that people trust and support.

Market Research

Global Dairy Market

Dairy products are in high demand worldwide. In 2024, the market was worth $947.11 billion and could reach $1,005.84 billion by 2032.

People want fresh, healthy, and eco-friendly milk, cheese, and yogurt. This is a great chance for farms that produce good-quality dairy.

U.S. Dairy Market Overview

The dairy market in the U.S. is growing fast. It’s worth about $111.6 billion in 2025 and could reach $133 billion by 2030. People want more fresh and local milk, and farms like SunnyVale Dairy can sell to both milk companies and local customers.

Florida & Okeechobee County

Florida has around 125,000 dairy cows that make about 300 million gallons of milk each year. Each cow gives around 6 to 8 gallons of milk a day. This shows that Florida’s dairy industry is active and has room to grow.

According to the Florida Farm Bureau, Okeechobee is one of the largest dairy-producing counties in Florida. It has many advantages:

- Close to markets: About 2 hours from Orlando and 3 hours from Miami.

- Good weather: Mild winters let cows graze all year.

- Support: Vets, feed, and transport are easy to get.

- Skilled workers: Local colleges and Future Farmers of America (FFA) programs provide trained farm workers.

SunnyVale will focus on eco-friendly farming and building a strong local brand, instead of just growing bigger.

Target Customers

SunnyVale Dairy Farms focuses on three main groups of customers.

1. Large Milk Processors

Big companies like Lactalis USA and Borden Dairy buy fresh milk in bulk every day. They are our main customers because they need a regular supply of clean, good-quality milk. Working with them gives SunnyVale steady sales and helps the farm stay strong.

2. Schools and Food Programs

Local schools in Okeechobee and Palm Beach Counties need milk for student meals. We want to supply them because it supports local families and provides long-term business. These customers also trust local farms that follow safe and clean practices.

3. Local Consumers

Families in Central and South Florida like buying fresh milk from nearby farms. They care about freshness, quality, and animal care. These customers will buy SunnyVale’s own brand of milk and dairy products when it launches in local stores.

These customers are important because they bring regular income, trust, and help the farm grow in the community.

Competitive Landscape

Florida’s dairy market has three main types of producers:

Large Processors (e.g., Larson Dairy, Alliance Dairies)

These farms manage 1,000–4,000 cows. They have economies of scale and strong contracts, but often face high costs, distant management, and less focus on sustainability.

Cooperative Farms (e.g., South Florida Farms Co-op)

Cooperatives share processing and distribution, which can lower costs. But they are often slower to innovate and less flexible for retail or branding.

Mid-Scale Independents (like SunnyVale)

Smaller farms are flexible, can use new technology, and attract eco-conscious customers. The challenge is a smaller production base, which requires efficiency and smart positioning.

SunnyVale combines wholesale processing contracts with retail sales, giving it stability, flexibility, and long-term growth potential.

SunnyVale’s Competitive Advantages

| Factor | SunnyVale Advantage |

|---|---|

| Animal Welfare | Certified humane herd management |

| Technology | Automated milking and data-driven feeding |

| Energy Use | Solar power + methane digester reduces costs 8–10% |

| Market Access | Dual-channel: processors + retail |

| Brand Identity | “Fresh From Florida” certification & sustainability marketing |

By using modern technology, eco-friendly methods, and a strong local brand, SunnyVale is set to stand out, build customer loyalty, and grow steadily over the next few years.

Market Trends

Several trends work in SunnyVale’s favor:

- Sustainability premium: Retailers and processors pay 2–3% more for milk from low-carbon, animal-welfare-certified farms. SunnyVale’s methane digester and rotational grazing qualify.

- Local demand: Florida consumers like locally produced dairy, with local milk sales growing about 10% per year.

- School programs: Florida Department of Agriculture and Consumer Services (FDACS) programs encourage schools to buy from in-state farms. SunnyVale plans to secure two district supply contracts by Year 2.

- Supply chain stability: Post-COVID, processors prefer local suppliers to save on shipping and reduce spoilage.

Stop Googling competitors for hours

Production & Products

Herd Structure and Growth

SunnyVale Dairy Farms has Holstein–Friesian cows, which give a lot of milk and do well in Florida’s warm weather. The farm starts with 180 milking cows and will grow slowly to keep milk quality and herd health good.

| Year | Milking Cows | Replacement Heifers | Total Herd | Milk Output (gal) |

|---|---|---|---|---|

| Year 1 | 180 | 40 | 220 | 462,000 |

| Year 2 | 210 | 45 | 255 | 525,000 |

| Year 3 | 240 | 50 | 290 | 590,000 |

Each cow will give about 22,000 lbs (~2,566 gallons) of milk per year. About 25% of cows are replaced each year to keep the herd healthy and milk production steady.

Production System & Suppliers

SunnyVale Dairy Farms uses modern technology and local suppliers to make milk efficiently, sustainably, and of good quality.

1. Milking technology

SunnyVale Dairy Farms uses the DeLaval VMS V300 machine to milk cows gently all day. It helps keep cows calm and healthy while checking their milk and feed. The system also spots early signs of sickness like mastitis.

Each cow is milked about 2 times per day, which helps increase milk yield by roughly 6% while keeping the cows comfortable and healthy.

2. Feed and nutrition

SunnyVale’s feed comes from Cargill Feed & Nutrition, a local Okeechobee supplier, under a 3-year fixed-price contract. The cows are fed a carefully balanced daily diet that includes:

- 60% silage

- 25% grain

- 10% hay

- 5% supplements

The farm grows 20% of its own silage, which saves money on feed and requires less from outside. BioTek Solutions makes sure the cows get the right food and nutrients without waste.

3. Animal health and welfare

Animal care is a top priority at SunnyVale. The farm follows a detailed health plan that includes:

- Vet visits every two weeks and helps anytime in emergencies

- Routine care like vaccination, hoof trimming, and parasite control

- A goal to get Certified Humane status by Year 2

- Calves are raised in a separate, ventilated, temperature-controlled barn to ensure proper growth and safety

Veterinary services are managed through a contract with South Central Vet Group, at a cost of $2,200 per month.

4. Milk handling and processing

Milk is stored in an 8,000-gallon tank at 38°F or below. Florida Milk Logistics picks up and delivers milk daily to processors.

By Year 3, SunnyVale will install a small Tetra Pak pasteurization system to bottle its own milk and cream for local stores, with supplies from Tetra Pak’s Miami center.

Products & Experiences

SunnyVale sells fresh, good-quality milk, cream, butter, and yogurt. The farm also offers tours and sells compost made from cow manure.

Sustainability Systems

SunnyVale works to save energy and protect the land:

- Cow manure is turned into energy and compost, covering 25% of electricity needs

- Solar panels provide another 30% of power

- Recycled water is used to clean barns and water pastures

- Moving cows between pastures saves feed and keeps soil healthy

- The farm may earn carbon credits in the future

These steps help SunnyVale save money and protect the environment.

Production Costs (per cwt of Milk)

| Expense | % of Total | Cost ($/cwt) |

|---|---|---|

| Feed | 40% | $7.60 |

| Labor | 25% | $4.75 |

| Veterinary & Breeding | 7% | $1.33 |

| Utilities & Fuel | 4% | $0.76 |

| Maintenance | 3% | $0.57 |

| Overhead | 21% | $3.99 |

| Total | 100% | $19.00 |

This cost structure ensures SunnyVale remains profitable, even if Florida milk prices fluctuate between $19–$21 per cwt.

Operations & Staffing

SunnyVale Dairy Farms runs daily from 4:30 AM to 8:00 PM with two milking shifts.

- Morning: 4:30 AM to 12:30 PM

- Evening: 12:30 PM to 8:00 PM

Staffing Plan

SunnyVale Dairy Farms has a small team working every day to care for the cows, handle milking, and run the farm smoothly.

| Role | Staff Needed | Job | Pay |

|---|---|---|---|

| Owner/Operator | 1 | Runs the farm and takes care of the cows | $60,000/year |

| Operations Manager | 1 | Manages daily work and staff | $55,000/year |

| Herd Manager | 1 | Looks after cow health and feeding | $48,000/year |

| Dairy Technicians | 4 | Milking, checking milk quality, and helping the herd | $37,000/year |

| Maintenance/Mechanic | 1 | Fixes equipment and barns | $41,000/year |

| Seasonal Farmhands | 2 | Help with chores during busy months (4 months/year) | $15/hour |

Automated milking reduces labor by 25–30% compared to normal farms. Each technician handles about 40 cows per shift. Real-time tracking of cow health and production metrics through DeLaval’s Herd Navigator improves efficiency and early disease detection. Staff are trained in multiple tasks to keep operations smooth.

Vendor & Partner Network

Vendor agreements are reviewed annually by Melissa Whitmore to maintain cost control and compliance consistency.

| Vendor / Partner | Service | Contract Terms |

|---|---|---|

| Cargill Feed & Nutrition | Feed supply (3-year contract) | Fixed feed pricing for stability |

| BioTek Solutions | Veterinary & herd health services | Monthly retainer + emergency coverage |

| DeLaval North America | Milking systems installation & maintenance | Annual service agreement ($12,000/yr) |

| Florida Milk Logistics | Milk transportation | $0.14/gal fixed through 2028 |

| Stericycle | Waste & biohazard removal | Annual contract |

| CPA Firm | Financial reporting & USDA compliance | Quarterly reviews |

Compliance & Regulatory Management

SunnyVale Dairy Farms will fully comply with state, federal, and USDA requirements for dairy operations:

- FDACS Grade “A” Dairy Permit: Ensures milk quality and sanitation standards.

- EPA Livestock Wastewater Certification: Governs manure and lagoon management.

- USDA Dairy Plant Number: Required for processor and retail sales.

- Animal Welfare Certification (Certified Humane): Targeted by Year 2.

- OSHA Farm Safety Compliance: Employee safety and equipment handling protocols.

All certifications and renewals will be tracked through an internal compliance calendar, reviewed quarterly by management.

Daily Workflow

SunnyVale Dairy Farms starts work at 4:30 AM with morning milking. At 6:00 AM, cows are fed, checked for health, and stalls are cleaned. By 9:00 AM, equipment is cleaned and milk is prepared for delivery. Around 12:00 PM, the manager does office work and orders supplies. Evening milking begins at 4:00 PM. At 6:30 PM, cows go to pastures, and equipment is checked. The day ends at 8:00 PM with data updates to get ready for the next day.

Technology Integration

Modern tools help SunnyVale run smoothly:

- DeLaval VMS Dashboard: Monitors yield per cow, udder health, and milk flow efficiency.

- FarmLogs Software: Tracks feed inventory, grazing rotation, and field health for silage production.

- QuickBooks + AgAmerica Online Portal: Used for lender reporting, cash flow tracking, and financial forecasting.

- IoT Sensors: Detect temperature, humidity, and methane levels in barns for animal comfort optimization.

Milestones & Timeline

SunnyVale Dairy Farms has a clear plan for growth, with key milestones and timelines to guide the farm from startup to a fully operational, profitable dairy business.

Does your business plan feel generic or unclear?

Customize your plan to adapt to investor/lender interests

Sales & Marketing Strategy

Strategic Objective

SunnyVale Dairy Farms aims to balance steady sales to large processors with the growth of our local brand. In the first 18 months, we focus on long-term processor contracts for stable income. From Year 2 onward, we’ll expand our “SunnyVale Fresh Dairy” brand through retail and value-added products like butter and yogurt.

Sales Channels

SunnyVale Dairy Farms has a smart plan to sell its products and grow its brand. We focus on three main ways to reach customers while keeping income steady and building recognition:

- Selling to Milk Processors (70% of sales)

Most of SunnyVale’s milk goes to large processors like Lactalis USA and Borden Dairy. These contracts provide consistent demand and quick payment, helping the farm manage costs and grow steadily. In the first year, the farm plans to sell about 3.9 million pounds of milk to processors.

- Supplying Schools and Institutions (20% of sales)

SunnyVale also works with local schools and co-ops, including Okeechobee and Palm Beach County school districts. These agreements provide stable pricing and guaranteed volumes, supporting both the farm and community nutrition programs. The farm’s “Fresh From Florida” certification helps qualify for these programs.

- Retail and Brand Sales (10% of sales)

SunnyVale sells milk, butter, and yogurt directly to grocery stores under the brand “SunnyVale Fresh Dairy.” Retail sales offer higher profit margins and help the farm build a strong local presence. By Year 3, the farm will offer small-batch yogurt, cream, and butter in ten Orlando and Palm Beach stores.

Marketing Channels

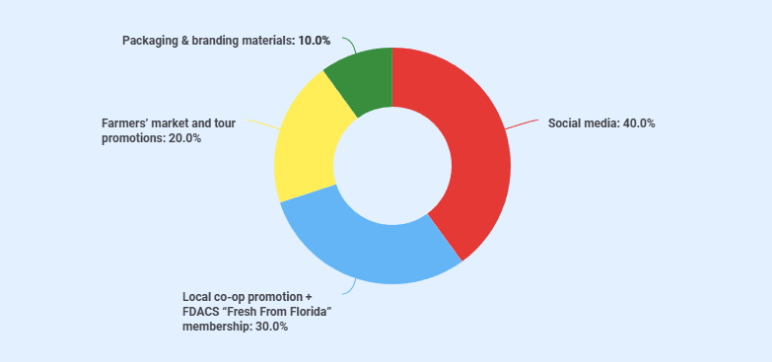

Marketing spend will grow from $2,000/month in Year 1 to $3,500/month by Year 3, with funds allocated as:

| Marketing Activity | Percentage | Budget ($) | Description |

|---|---|---|---|

| Social media (Facebook, Instagram for farm brand) | 40% | $800 | To share farm updates, photos, and product news online. |

| Local co-op promotion + FDACS “Fresh From Florida” membership | 30% | $600 | To join local programs and promote SunnyVale as a local Florida brand. |

| Farmers’ market and tour promotions | 20% | $400 | To attract visitors and local buyers through markets and farm tours. |

| Packaging & branding materials | 10% | $200 | To design labels, flyers, and signs for SunnyVale products. |

| Total | 100% | $2,000 | — |

Promotions & Community Activities

To connect with customers, SunnyVale will use simple, friendly promotions:

- “Meet the Cow” farm days: Monthly farm tours where people can see how milk is made and meet the cows.

- Local store discounts: Special offers for grocery stores that sell SunnyVale milk and butter.

- Social media sharing: Regular posts showing farm life, animal care, and eco-friendly practices.

- Community support: Partnering with 4-H clubs, FFA programs, and local events to build strong community ties.

Sales Targets & Customer Acquisition Plan

| Year | Key Focus | Customer Acquisition Goals | Total Revenue ($) | Processor Volume (% of Total) | Retail Revenue ($) |

|---|---|---|---|---|---|

| Year 1 | Build the Base | Secure 3 wholesale processor contracts | $947,100 | 100% | — |

| Year 2 | Expand to Institutions | Add 2 school district supply deals | $1,128,750 | 85% | $170,000 |

| Year 3 | Grow the Brand | Launch branded retail line with 10 Orlando/WPB retailers | $1,327,500 | 70% | $400,000 |

By Year 3, SunnyVale expects retail and institutional channels to contribute nearly 30% of total revenue, providing margin expansion and brand equity beyond bulk supply operations.

Don’t spend weeks on your first draft

Complete your business plan in less than an hour

Financial Plan

SunnyVale Dairy Farms’ financial plan is based on realistic, production-based modeling that reflects the actual cost of building and running a mid-size dairy in Florida. The goal is to balance startup investment, stable revenue growth, and long-term sustainability.

In the first year, most of the focus will be on setting up the farm and reaching full milk production. From Year 2 onward, efficiency and sales expansion are expected to improve profits.

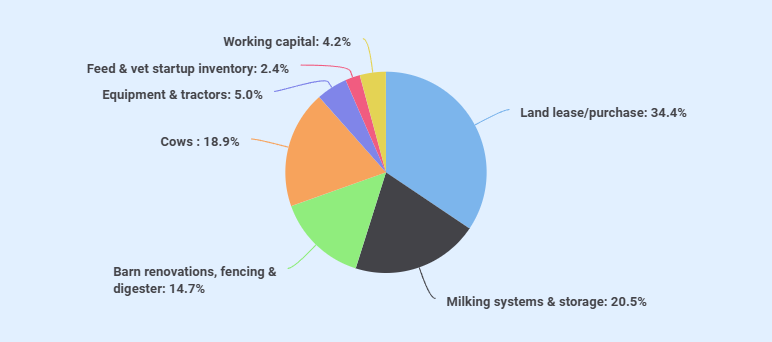

Startup Costs

The farm will require about $1.91 million to start operations. This includes land, equipment, animals, and working capital.

| Category | Description | Amount (USD) |

|---|---|---|

| Land lease/purchase | 80 acres @ $8,200/acre | $656,000 |

| Milking systems & storage | DeLaval + 2×2,000-gallon tanks | $390,000 |

| Barn renovations, fencing & digester | Infrastructure & manure system | $280,000 |

| Cows (180 Holsteins @ $2,000) | Dairy herd | $360,000 |

| Equipment & tractors | Operational machinery | $95,000 |

| Feed & vet startup inventory | Initial feed and medical stock | $45,000 |

| Working capital | Operating liquidity | $80,000 |

| Total Required Capital | ≈ $1.91M Funded by $950k loan + $280k equity + land lease credit + vendor terms |

Important Assumptions

- Herd expansion: 180 → 240 head by Year 3

- Average milk yield: ~2,566 gallons per cow annually at full capacity

- Milk price escalation: $2.05 → $2.25 per gallon over 3 years

- Debt term: 15 years at 5.5% fixed interest

- Working capital coverage: 3 months of expenses

- Production: Improves by 7–8% annually

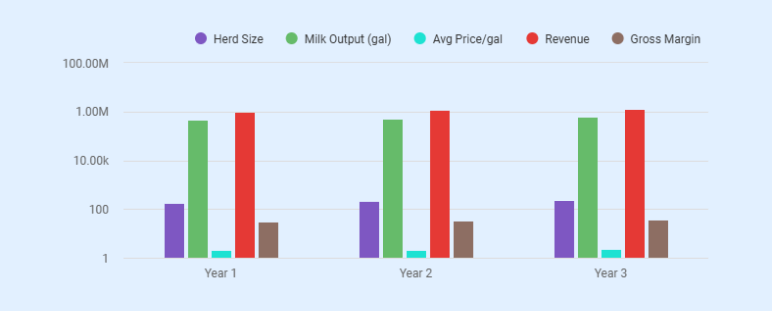

Revenue Forecasts

| Year | Herd Size | Milk Output (gal) | Avg Price/gal | Revenue | Gross Margin |

|---|---|---|---|---|---|

| 1 | 180 | 462,000 | $2.05 | $947,100 | 32% |

| 2 | 210 | 525,000 | $2.15 | $1,128,750 | 35% |

| 3 | 240 | 590,000 | $2.25 | $1,327,500 | 37% |

Monthly Projections (Year 1)

| Month | Revenue ($) | COGS ($) | Operating Expenses ($) | Net Income ($) |

|---|---|---|---|---|

| Jan | $73,000 | $49,800 | $39,200 | −$16,000 |

| Feb | $74,000 | $50,400 | $39,000 | −$15,400 |

| Mar | $76,000 | $51,800 | $38,500 | −$14,300 |

| Apr | $77,000 | $52,000 | $38,000 | −$13,000 |

| May | $78,000 | $52,000 | $38,000 | −$12,000 |

| Jun | $79,000 | $52,000 | $37,800 | −$10,800 |

| Jul | $80,000 | $52,000 | $37,500 | −$9,500 |

| Aug | $81,000 | $52,000 | $37,000 | −$8,000 |

| Sep | $82,000 | $52,000 | $36,500 | −$6,500 |

| Oct | $83,000 | $51,900 | $36,000 | −$4,900 |

| Nov | $84,000 | $51,900 | $35,500 | −$3,400 |

| Dec | $80,100 | $48,300 | $33,000 | +$1,200 |

| Total | $947,100 | $628,100 | $456,000 | −$85,000 |

Projected Profit & Loss Statement (3 Years)

| Category | Year 1 | Year 2 | Year 3 |

|---|---|---|---|

| Herd Size | 180 | 210 | 240 |

| Milk Output (gallons) | 462,000 | 525,000 | 590,000 |

| Average Price ($/gal) | $2.05 | $2.15 | $2.25 |

| Total Revenue | $947,100 | $1,128,750 | $1,327,500 |

| COGS | $643,000 | $733,000 | $836,000 |

| Gross Profit | $304,100 | $395,750 | $491,500 |

| Gross Margin | 32% | 35% | 37% |

| Operating Expenses | $450,000 | $450,000 | $450,000 |

| EBITDA | −$145,900 | −$54,250 | $41,500 |

| Debt Service | $125,000 | $125,000 | $125,000 |

| Net Income Before Tax | −$85,000 | $95,000 | $215,000 |

| Net Margin | −9% | 8% | 16% |

Projected Balance Sheet (3 Years)

| Category | Year 1 | Year 2 | Year 3 |

|---|---|---|---|

| ASSETS | |||

| Current Assets | |||

| Cash & Working Capital | $80,000 | $95,000 | $160,000 |

| Feed & Vet Inventory | $45,000 | $50,000 | $55,000 |

| Accounts Receivable | $40,000 | $45,000 | $50,000 |

| Total Current Assets | $165,000 | $190,000 | $265,000 |

| Fixed Assets | |||

| Land & Buildings (net of depreciation) | $600,000 | $590,000 | $580,000 |

| Milking Systems & Storage | $390,000 | $375,000 | $360,000 |

| Equipment & Tractors | $95,000 | $88,000 | $81,000 |

| Dairy Herd (biological assets) | $360,000 | $420,000 | $480,000 |

| Total Fixed Assets | $1,445,000 | $1,473,000 | $1,501,000 |

| TOTAL ASSETS | $1,610,000 | $1,663,000 | $1,766,000 |

| LIABILITIES & EQUITY | |||

| Current Liabilities | |||

| Accounts Payable | $25,000 | $30,000 | $35,000 |

| Short-term Notes / Current Loan Portion | $60,000 | $60,000 | $60,000 |

| Total Current Liabilities | $85,000 | $90,000 | $95,000 |

| Long-Term Liabilities | |||

| USDA-Backed Loan (AgAmerica, 15 yrs @ 5.5%) | $890,000 | $830,000 | $765,000 |

| Total Liabilities | $975,000 | $920,000 | $860,000 |

| Owner’s Equity | |||

| Owner Capital (initial equity) | $280,000 | $280,000 | $280,000 |

| Retained Earnings | $355,000 | $463,000 | $626,000 |

| Total Owner’s Equity | $635,000 | $743,000 | $906,000 |

| TOTAL LIABILITIES & EQUITY | $1,610,000 | $1,663,000 | $1,766,000 |

Spreadsheets are exhausting & time-consuming

Build accurate financial projections w/ AI-assisted features

Projected Cash Flow (3 Years)

| Category | Year 1 | Year 2 | Year 3 |

|---|---|---|---|

| CASH INFLOWS | |||

| Milk Sales Revenue | $947,100 | $1,128,750 | $1,327,500 |

| Owner Equity Contribution | $280,000 | — | — |

| USDA-Backed Loan (AgAmerica) | $950,000 | — | — |

| Other Credits (Land lease credit, vendor deferrals) | $280,000 | — | — |

| Total Cash Inflows | $2,457,100 | $1,128,750 | $1,327,500 |

| CASH OUTFLOWS | |||

| Land Purchase / Lease | $656,000 | — | — |

| Milking Systems & Storage | $390,000 | — | — |

| Barn Renovations + Digester | $280,000 | — | — |

| Cows (Initial Herd Purchase) | $360,000 | $60,000 | $60,000 |

| Equipment & Tractors | $95,000 | — | — |

| Feed & Vet Inventory (startup) | $45,000 | $50,000 | $55,000 |

| Operating Expenses | $450,000 | $450,000 | $450,000 |

| Loan Payments (Principal + Interest) | $125,000 | $125,000 | $125,000 |

| Maintenance & Utilities | $30,000 | $35,000 | $40,000 |

| Total Cash Outflows | $2,431,000 | $720,000 | $730,000 |

| NET CASH FLOW (before tax) | +$26,100 | +$408,750 | +$597,500 |

| Beginning Cash Balance | — | $26,100 | $434,850 |

| Ending Cash Balance | $26,100 | $434,850 | $1,032,350 |

Break-Even Analysis

| Item | Details |

|---|---|

| Average Selling Price (per gallon) | $2.05 |

| Variable Cost (per gallon) | $1.39 (≈68% of selling price, based on COGS structure) |

| Contribution Margin (per gallon) | $0.66 |

| Break-Even Volume (gallons) | ≈410,000 gallons |

| Break-Even Revenue | 410,000 × $2.05 = $840,500 |

| Current Year 1 Output | 462,000 gallons (≈112% of break-even point) |

Business Ratios

| Ratio | Formula / Definition | Year 1 | Year 2 | Year 3 |

|---|---|---|---|---|

| Gross Margin | Gross Profit ÷ Revenue | 32% | 35% | 37% |

| Net Profit Margin | Net Income ÷ Revenue | −9% | 8% | 16% |

| Current Ratio | Current Assets ÷ Current Liabilities | 1.94 | 2.11 | 2.79 |

| Debt-to-Equity Ratio | Total Liabilities ÷ Owner’s Equity | 1.54 | 1.24 | 0.95 |

| Return on Assets (ROA) | Net Income ÷ Total Assets | −5% | 6% | 12% |

| Return on Equity (ROE) | Net Income ÷ Owner’s Equity | −13% | 13% | 24% |

| Operating Expense Ratio | Operating Expenses ÷ Revenue | 47% | 40% | 34% |

| Break-Even Coverage Ratio | Actual Sales ÷ Break-Even Sales | 1.13 | 1.38 | 1.58 |

Funding Requirements

Loan Overview

SunnyVale Dairy Farms is asking for a USDA-backed farm loan through AgAmerica Lending, Lakeland, FL. The loan amount is $950,000 with a 15-year term and 5.5% fixed interest. This money will help start the farm and cover early costs.

Purpose of the Loan

The loan will pay for:

- Land lease or purchase and barn/fence improvements

- Milking equipment and storage tanks

- 180 Holstein cows

- Initial feed, veterinary care, and working capital

This ensures SunnyVale can start smoothly and grow safely.

Collateral Summary

The loan is backed by:

- Dairy herd: $420,000

- Land and barn improvements: $600,000

These assets give the lender confidence.

Repayment Plan & DSCR

Loan repayments are spread over 15 years at 5.5% fixed interest. With stable milk contracts and growing retail sales, SunnyVale expects a debt service coverage ratio (DSCR) of 1.3× or more by Year 3, meaning the farm can comfortably pay back the loan.

The owner’s $280,000 equity also adds financial strength and lowers the lender’s risk.

Risk & Mitigation

Running a dairy farm has risks, like higher feed costs, sick cows, or not enough workers. SunnyVale Dairy Farms handles these risks with smart planning, long-term deals, and trusted partners. These steps help keep the farm’s production and finances stable under the USDA-FSA framework.

| Risk Area | Impact | Mitigation Measures |

|---|---|---|

| Feed Price Volatility | Feed makes up about 40% of all costs. If corn, soy, or silage prices rise, profit can drop and cash flow is affected. |

|

| Milk Price Fluctuations | Milk prices can vary by 10–15%, affecting income and debt coverage. |

|

| Herd Health & Disease | Illness or fertility problems can lower milk yield and increase veterinary costs. |

|

| Labor Availability & Turnover | Lack of skilled dairy workers or high turnover can reduce productivity. |

|

The Quickest Way to turn a Business Idea into a Business Plan

Fill-in-the-blanks and automatic financials make it easy.