You’re sitting there, thinking about starting your own manufacturing business, but the questions keep piling up.

- Which product should I manufacture to have real demand?

- What machines and production setup do I actually need?

- Where will I find skilled workers who can run a factory efficiently?

And most importantly, how do I make sure I don’t burn through money before I even see my first sale?

It feels overwhelming because there’s so much to consider, and one wrong move can cost months of effort and a lot of money. The process seems complex, and it’s easy to get stuck before you even start.

That’s exactly why this guide exists. I’m going to walk you through the entire journey step by step, from picking your product, setting up your production line, hiring the right team, to launching and selling your product.

By the end, you’ll have a clear, practical roadmap to starting your manufacturing business without getting lost in the chaos.

Let’s begin.

Why now is the perfect time to start a manufacturing business?

Global events, like the recent U.S. tariffs, are changing manufacturing and sectors in the period we live in.

Businesses are being forced to reconsider their supply chains and production plans as a result of the ongoing changes in trade policy, tariffs, and geopolitical initiatives by the superpowers—China, Russia, and the United States.

Global trade is now even more unpredictable as a result of the Russia-Ukraine war, Middle East tensions, and interruptions brought on by the environment. But these adjustments also present a big chance for regional producers to expand and close the gap.

In actuality, nations all around the world are putting more effort into growing their own manufacturing sectors. Mexico is growing in electronics and automation, while nations like India are producing semiconductors.

Let’s take a closer look at how key countries are shaping their manufacturing strategies and what that means for entrepreneurs looking to seize these opportunities:

| Country | Current Focus | Why It Matters |

|---|---|---|

| United Kingdom | Post-Brexit domestic production | Reduces reliance on imports, encourages “Made in UK” goods |

| France | Investment in advanced and green manufacturing | Positions the local industry for long-term sustainability and innovation |

| China | Moving from low-cost labor to automation and high-tech | Raises competition, but also creates space for U.S. firms to compete on quality and trust |

What does this mean for you? It shows a clear global trend: Nations are realizing that strong local manufacturing isn’t optional anymore; it’s a necessity. Thus, if you’re thinking about business, do think about starting with manufacturing.

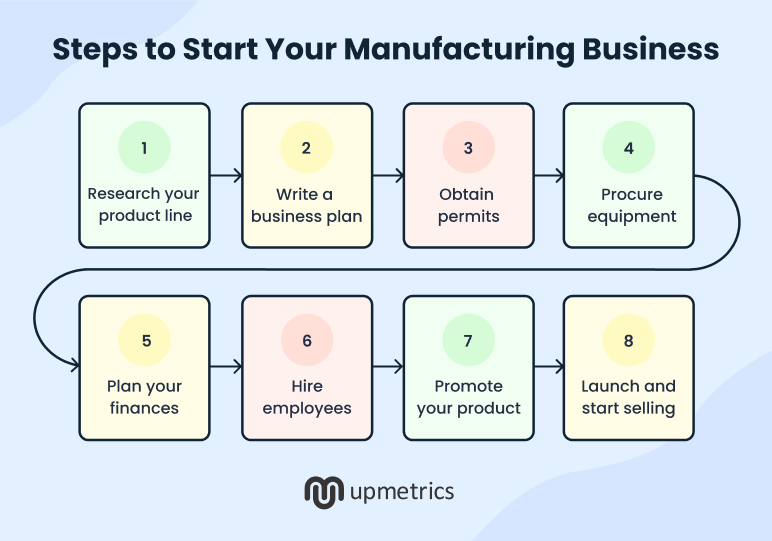

8 Steps to start your manufacturing business

When I first started working with manufacturing founders, one thing became clear: Most weren’t short on ideas; they were drowning in them. One day it was furniture, the next it was organic skincare, and by Friday they were considering solar panels.

That’s exactly why structure matters at the start. Manufacturing isn’t like launching an online store. You’re dealing with equipment, suppliers, compliance, and real capital on the line. These eight steps will help you cut through the noise, make grounded decisions, and move from “what if” to “let’s build.”

Step 1: Research and choose your niche

Before launching a manufacturing company, you must first decide what you will manufacture. This may seem self-evident, but believe me when I say that the majority of new business owners either skip this phase or choose a venture just because it “sounds profitable.” That is insufficient.

Begin by determining whether there is a genuine need for this product. Examine market patterns, see who is purchasing, and find out why.

Products related to home remodeling, healthcare, and sustainability, for instance, are currently becoming more popular in the United States. Your foundation will be considerably stronger if you can adapt to these expanding needs.

Then consider the competition. It will be difficult to break in if too many producers are currently producing the same item. But if you can identify a small gap in the market, maybe a variation of a popular product or a more affordable version, you can stand out.

Also, don’t ignore practicality. Can you source raw materials easily? Can the product be made with the resources you have access to? A niche that looks attractive on paper but is impossible to produce profitably won’t take you far.

Here’s a simple way to test your idea:

- Look for demand (are people buying it?)

- Check supply gaps (is there space for a new player?)

- Study costs (can you make it at a profit?)

If your idea passes these three checks, you’ve got a solid niche to build on. For more in-depth guidance, you can also explore examples of manufacturing business plans. They help with structuring your plan, forecasting finances, and making informed decisions quickly.

Remember, this step is about setting the foundation. If you choose the wrong niche, every step after this will be harder. However, if you make a wise choice, the rest of your journey becomes much smoother.

Step 2: Write a detailed business plan

Once you’ve chosen your niche, the next step is to put everything on paper. A business plan isn’t just something banks or investors ask for; it’s your roadmap.

It helps you stay focused, avoid costly mistakes, and see the bigger picture before you start spending money. Remember, creating a business plan isn’t about writing a 50-page document; a one-page business plan with clear goals is enough to get you started.

Here’s how you can draft your first business plan:

- Start with your idea

- Define your target market

- Map your production process

- Plan your supply chain

- Create a marketing approach

- Do a basic financial forecast

- Set growth milestones

Don’t worry if your first draft isn’t perfect. A business plan is a living document; you’ll update it as you learn more. The goal is to give yourself clarity and direction before you dive in.

Need help in crafting a business plan?

Let Upmetrics AI help create your plan in minutes

Plans starting from $14/month

Step 3: Obtain permits and regulatory requirements

Just like a small business needs permission to operate, a manufacturing business also requires permits, often even more than a regular small business.

These permissions aren’t just formality; they’re legal requirements. Ensure to include them in your business strategy. Skipping this step can cost you heavy fines or, worse, force you to shut down.

Let’s break down the most common permit requirements and how to obtain them:

| Permit/License | Why It’s Needed | Where to Get It | Approx. Fees |

|---|---|---|---|

| Business License | Allows you to legally operate your business | Local city/county office | $50 – $500 annually |

| Zoning Permit | Ensures your factory is in an approved location | City zoning department | $100 – $250 |

| Environmental Permit | Required if your manufacturing impacts air, water, or waste | EPA or state environmental agency | $500 – $5,000+ depending on scale |

| Health & Safety Permits | Certifies workplace meets OSHA safety standards | OSHA or state agency | Varies (inspection-based) |

| Sales Tax Permit | Required if selling products directly | State Department of Revenue | Usually free or a small fee |

| Special Industry Permits | Industry-specific (e.g., food, chemicals, firearms) | Federal/state authorities | Varies widely |

| Permit/License | Where to Get It | Approx. Fees | Process/Notes |

|---|---|---|---|

| Business License | Local city/county office | $50 – $500 annually | Apply with basic business info; renew annually |

| Food Manufacturing Permit | State Department of Health | $200 – $1,000 | Inspection required; approval before production starts |

| Food Handler/Employee Health Permit | Local Health Department | $10 – $50 per employee | Employees may need a short course or certification |

| Zoning Permit | City zoning department | $100 – $250 | Submit facility layout and address; approval may take 1–2 weeks |

| Sales Tax Permit | State Department of Revenue | Usually free or a small fee | Register online; it enables the collection of sales tax |

| FDA Registration (if applicable for certain foods) | FDA | No fee for registration | Complete online registration; the facility may be inspected periodically |

Step 4: Procure equipment and set up production lines

In manufacturing, your machines are the backbone. Without the right setup, even the best business plan won’t work.

Thus, the first thing you should know is your process. Write down every step of how your product will be made. Then match each step with the machine or tool required. Don’t just copy what others are using; consider your scale, budget, and the type of quality you want.

Now, decide how to invest. Buying brand-new equipment may look great, but it can quickly drain your capital. Instead, leasing or buying used machines is often a smarter move in the beginning.

After understanding the process and deciding on investments, the next step is to set up your production line for optimal flow.

What’s a production line?

A production line is the step-by-step path your product follows inside the factory, from raw materials to finished goods. Each machine or worker handles one step, making the process faster and more organized.

Now, how do you set it up? Imagine raw material entering one side of the factory and the finished product leaving the other side without unnecessary back-and-forth. Place machines in order of process, keep enough space for movement, and ensure materials flow smoothly in one direction. That layout saves time, reduces mistakes, and cuts costs.

And one more thing, don’t forget training and maintenance. A machine is only as good as the person running it. Plus, regular servicing keeps your production line moving without costly breakdowns.

Step 5: Plan your finances and secure funding

The largest obstacle to launching a manufacturing company isn’t the concept but rather the initial funding required. Rent and salaries aren’t the only expenses in production.

Permits, insurance, qualified personnel, bulk raw materials, and heavy machinery are all necessary. This implies that if you don’t have a solid financial strategy, you’ll run out of fuel before you’ve even started.

That’s why you need to plan your finances carefully, so money never slows down your manufacturing process.

But how do you do that? Here’s a clear breakdown to help you:

| Funding Option | How It Works | Required Documents | Typical Timeline |

|---|---|---|---|

| Personal Savings | Use your own funds to cover startup costs | None (personal funds) | Immediate |

| Bank Loans (SBA Loans) | Borrow from banks with lower interest via an SBA guarantee | Business plan, financial forecast, credit report | 4–12 weeks |

| Equipment Financing/Leasing | Get loans/leasing specifically for machinery | Equipment quote, business details, collateral (sometimes) | 2–6 weeks |

| Grants & Government Programs | Federal/state incentives for industries like green energy, food, or local jobs | Application form, project proposal, compliance docs | 1–6 months |

| Angel Investors/VCs | Raise funds in exchange for equity | Pitch deck, business plan, financial model | 2–6 months (depends on negotiations) |

| Crowdfunding (Kickstarter, etc.) | Raise smaller amounts from many supporters | Campaign page, product prototype, marketing plan | 1–3 months |

| Community/Local Investment Programs | Regional funds supporting local manufacturing | Application, proof of impact (jobs, economic growth) | 1–3 months |

Match your funding need with the option. For quick cash, personal savings, or equipment leasing may work. For long-term stability, SBA loans or grants can be better.

Step 6: Hire the right employees

In manufacturing, machines do the work, but it’s people who keep everything running smoothly. The real challenge isn’t just hiring employees; it’s finding skilled ones.

Fortunately, today there are plenty of platforms and resources that make this easier. Some of the most effective options include:

Using these platforms, you can hire full-time, part-time, or freelance workers. Another way is to reach out through your industry associations or professional groups. However, remember: Don’t hire just anyone. Set clear limits and parameters, and only hire candidates who truly fit your requirements.

For example, if you’re starting a food manufacturing business and need someone to test products, define the required skills and criteria first. Here’s a simple table to guide your selection:

| Parameter | What to Look For |

|---|---|

| Qualification | Degree or certification in food science, nutrition, or a relevant field |

| Experience | 1–3 years in food testing, quality control, or manufacturing |

| Technical Skills | Ability to use testing equipment, understand lab results |

| Attention to Detail | Checks every batch thoroughly, notices inconsistencies |

| Reliability | Punctual, consistent, and committed |

| Communication Skills | Can report results clearly and follow instructions |

This table makes it easy to set hiring standards and ensures you bring in people who can actually contribute to your manufacturing process from day one.

Step 7: Promote your product

Marketing a manufacturing product is a bit different from the retail industry. Manufacturers don’t usually market directly to end customers. Instead, their real target audience is suppliers, distributors, or wholesale businesses.

For the manufacturer, it’s not about making a reel and uploading it on TikTok. Then how do you promote in such a setup? Here’s how you can promote your product as a manufacturer:

Marketing a manufacturing product is a bit different from the retail industry. As a manufacturer, you don’t usually market directly to end customers. Instead, their real target audience is suppliers, distributors, or wholesale businesses.

For the manufacturer, it’s not about making a reel and uploading it on TikTok. So how do you promote in such a setup? Here are some practical ways:

1. Marketing via email

B2B email still works. Create a focused list of industry buyers, suppliers, and distributors. Provide technical details, case studies that demonstrate how your product addresses their issue, and product updates. Maintain a professional yet understandable tone.

2. Create a website with quality content

Customers frequently visit your website first. Pay attention to product features, certifications, pricing models, and customer reviews rather than just making it appear nice. Include articles or blogs that address issues unique to your sector. This increases your trustworthiness and facilitates your discovery.

3. Make an SEO investment

If no one visits a well-designed website, it is worthless. When someone searches for terms like “bulk packaging supplier” or “metal parts manufacturer,” SEO helps your products show up. To increase rankings, speed up your website, and optimize keywords, hire an SEO specialist. This generates consistent, natural leads.

4. Run sponsored advertisements

For manufacturers, Google Ads and LinkedIn Ads are very effective. Target decision-makers, such as supply chain leaders, procurement managers, or wholesale purchasers, rather than squandering money on generic advertisements. Paid ads can help you reach them faster, especially in the early days.

5. Attend trade shows

Trade shows are where the big deals happen. Here, buyers, distributors, and competitors gather under one roof. By setting up a booth, you not only showcase your product but also build relationships face-to-face, which is still the most trusted form of marketing in B2B.

6. Participate in expos

Expos give you exposure on a larger stage, sometimes even globally. You get to network, understand industry trends, and build brand recognition. Additionally, being present at expos signals that you’re serious and established, which enhances your credibility.

By combining these strategies, you’ll put your product in front of the right people —the ones who actually make the purchasing decisions.

Step 8: Launch production and start selling

You’ve done the research, set up your factory, hired the team, and promoted your product. Now it’s time to turn all that effort into action; launch production and start selling. This is where your idea becomes real, and revenue starts flowing.

| Step | Checklist Item | Notes/Tips |

|---|---|---|

| Pilot Production | Produce a small batch to test machines and workflow | Identify bottlenecks and fix issues before full-scale production |

| Quality Control | Inspect each unit for defects or inconsistencies | Set clear standards and record results for future reference |

| Packaging & Labeling | Finalize packaging design, labels, and safety info | Make it professional and compliant with regulations |

| Scale Production | Gradually increase output based on demand | Avoid overproduction to minimize waste and cash burn |

| Reach Out to Leads | Contact suppliers, distributors, and early clients | Personal calls or emails often work best in B2B |

| Provide Samples | Send product samples to potential buyers | Helps build trust and lets buyers experience quality firsthand |

| Set Pricing & Payment Terms | Decide wholesale/retail prices and payment schedules | Be clear and professional to avoid confusion later |

Now, to sell your product:

- Reach out to your existing leads

- Offer samples

- Set clear pricing and payment terms

- List your product on ThomasNet, Alibaba, or industry-specific directories

- Keep in touch with interested buyers constantly

Conclusion

If you’ve made it this far, it means you’re ready to take the next step and start your own manufacturing unit. Focus on building a strong foundation by following the steps we’ve discussed in this blog; from choosing the right product, securing permits, and hiring the right team, to promoting and selling your product. We’ve covered everything in detail so you can concentrate on creating a solid base for your business.

And if you need help planning and organizing your manufacturing unit, Upmetrics can simplify the process. It will help you manage your strategy, finances, and growth efficiently.

With the right foundation and tools in place, you’re all set to turn your plans into reality and make your manufacturing business a success.

The Quickest Way to turn a Business Idea into a Business Plan

Fill-in-the-blanks, AI-assistance, and automatic financials make it easy.