Executive Summary

Sunrise Acres Poultry Farm is a small broiler farm in Bulloch County, Georgia. The farm is at 8421 Old Orchard Road and has 400–500 broiler houses built for contract work with a major integrator. Each house has tunnel airflow, automatic feeding, water lines, and LED lights to keep the farm stable and efficient.

The farm is owned and run by Daniel Brooks and Hannah Brooks. Daniel brings 12 years of hands-on broiler house experience from Claxton Poultry. His background includes ventilation control, feed-line upkeep, late-cycle checks, and flock health monitoring. Whereas Hannah Brooks works on-site with him each day and helps manage both the daily work and the required records. This daily work fits into a wider poultry system that has long supported growers in the area.

And most importantly, Georgia is one of the top chicken-producing states in the U.S., and Bulloch County is one of its key centers. The area has strong local systems for growers, such as feed routes, litter buyers, service crews, and processing plants. This setup gives Sunrise Acres consistent contracts, stable income, and a clear process for each production cycle.

Most of the farm’s earnings come from its integrator, which provides chicks, feed, and pickup service. Payments are made based on bird health, growth, and overall results. We also earn a small amount from selling eggs from our family flock and compost to nearby farms.

In the first year, Sunrise Acres expects to make about $225,000. In the second year, income should reach around $235,000. By the third year, it may grow to about $250,000.

| Year | Revenue | Expenses | Net Profit/Loss |

|---|---|---|---|

| Year 1 | $225,000 | $235,000 | – $10,000 |

| Year 2 | $235,000 | $205,000 | + $30,000 |

| Year 3 | $250,000 | $195,000 | + $55,000 |

The farm is expected to move from a small loss in year 1 to a $30,000 gain in year 2 and a $55,000 gain in year 3 as the upgraded equipment begins to lower costs and improve flock performance.

To complete required upgrades and support early operations, Sunrise Acres is requesting a USDA loan of $480,000. About $230,000 of the funds will cover house improvements, a generator system, tools, supplies, and working capital for the first two cycles. The remaining portion of the loan package will support equipment financing and early operating needs tied to the integrator contract.

Business Overview

Legal Structure and Registration

Sunrise Acres Poultry Farm is a Georgia Limited Liability Company that will be formed in 2026. The LLC structure provides liability protection, a simple ownership setup, and clear reporting for USDA loan requirements.

Our farm operates from 8421 Old Orchard Road in rural Bulloch County, about twelve miles outside Statesboro. The area is a well-established farming corridor with poultry, peanuts, cotton, and steady agricultural activity. Sunrise Acres falls under industry classification NAICS 112320, Broilers and Other Meat-Type Chicken Production, which matches the farm’s contract-based broiler operation.

We at Sunrise Acres will maintain our operating account and loan servicing through the USDA Farm Service Agency – Georgia State Office. All bookkeeping and farm cycle records will be kept in QuickBooks and the integrator’s reporting platform.

Business Model

Sunrise Acres operates as a contract poultry farm. The integrator supplies the chicks, the chicken feed, the veterinary care, and the pickup schedules. We handle all daily work inside the houses, including bird care, temperature control, and recordkeeping.

Further, our core responsibilities are:

- Managing daily flock conditions

- Running the feeding, watering, and ventilation systems

- Keeping the houses clean and safe

- Monitoring bird growth and health

- Maintaining biosecurity logs and cycle reports

The model focuses on steady flock performance and the daily work required for each grow-out cycle. This keeps results consistent and provides predictable income under the integrator’s pay system.

Mission Statement

To raise healthy broilers through consistent care, responsible farm practices, and dependable day-to-day management.

Vision Statement

To build a reliable poultry operation in Bulloch County that delivers strong flock results, steady production cycles, and long-term farm stability, with room to grow once the business reaches full performance.

Ownership

| Owner | Title | Ownership % | Role and Responsibilities |

|---|---|---|---|

| Daniel Brooks | Founder & Farm Manager | 80% | Oversees daily flock care, equipment, ventilation, bird health checks, and house management |

| Hannah Brooks | Operations & Compliance Manager | 20% | Handles farm records, USDA paperwork, biosecurity logs, financial tracking, and cycle reporting |

Daniel Brooks will serve as the managing member and primary guarantor for the USDA loan. His background includes:

- 12 years of broiler house experience at Claxton Poultry

- Expertise in ventilation systems, feed-line management, welfare checks, and late-cycle monitoring

- Hands-on work with equipment repairs and daily house operations

Moreover, Hannah Brooks has agribusiness and USDA compliance experience. She manages environmental permits, paperwork, financial records, and all cycle-based reporting. Her work keeps the farm audit-ready at all times.

Industry & Market Landscape

U.S. poultry products are strong in both American and international markets because the industry has efficient production systems, good breeding lines, plenty of feed, and steady consumer demand. In 2024, the poultry sector earned about $70.2 billion, up from $67.4 billion in 2023.

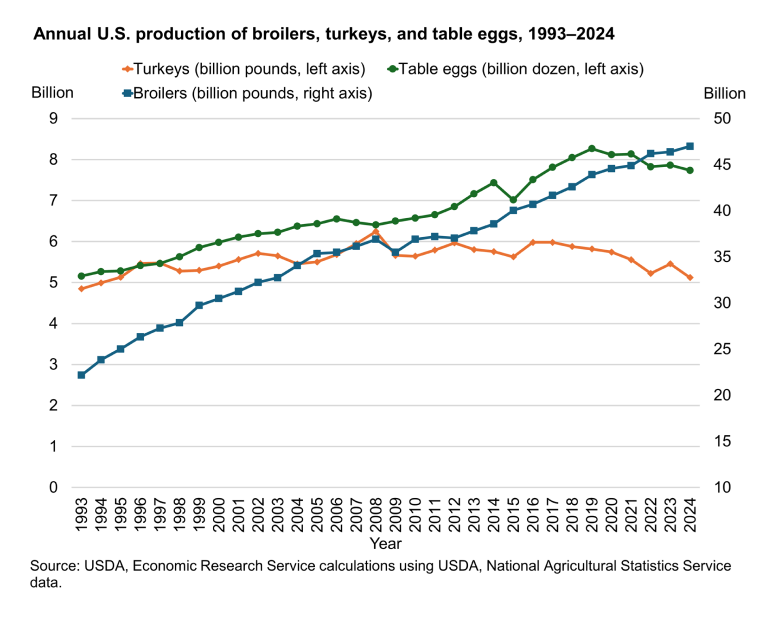

Moreover, the U.S. poultry production grew steadily from 2015 to 2024 as farms worked to meet rising demand at home and overseas. Broiler output increased by 17.3 percent, and table-egg production rose by 10.3% during this period. Turkey production, however, fell by 9.0% compared to 2015.

This long-term growth shows that chicken remains the most dependable and widely consumed protein in the country. For farms like Sunrise Acres, this steady demand supports consistent production cycles and a stable contract-farming environment.

Also, the report shows that broilers made up the largest share of the U.S. poultry market, reaching $45.4 billion in 2024, a 5.8 percent increase from the previous year. Broiler prices also rose slightly, while turkey production fell from $6.7 billion in 2023 to $3.7 billion in 2024. Egg production reached $21.0 billion in 2024, driven by strong pricing.

Other key points about the poultry industry include:

- Economic impact: The poultry industry supported 2.01 million jobs in 2024 and generated major state and federal revenue.

- Georgia’s production: Georgia remains the top chicken-producing state, with about 1.3 billion birds raised in 2023. Poultry made up 47 percent of the state’s agricultural output.

Bulloch County contribution: Research from the University of Georgia shows that counties with poultry farms earn higher farm income. A county with about 100 poultry houses can generate more than $4 million in gross farm income each year.

Target Market

Sunrise Acres serves two direct markets:

- Contract production with Pilgrim’s Pride

- Small local customers for eggs and compost

The contract market provides the main income. Local sales support community ties and add small, steady side revenue.

| Segment | Buyer/Partner Type | Needs | Sunrise Acres Advantage |

|---|---|---|---|

| Integrator (Pilgrim’s Pride) | Regional broiler company supplying chicks, feed, and schedules | Clean houses, stable care, strong biosecurity | Updated houses, reliable ventilation, and full compliance |

| Local Residents | Families near Statesboro buying fresh eggs | Freshness, fair pricing | Simple pickup system and clean handling |

| Local Crop Farmers | Farms using litter or compost for soil | Affordable nutrient-rich material | Clean litter handling and steady supply |

| Garden Centers / Home Gardeners | Community members needing compost | Consistent quality | Easy access at fair prices |

| Schools / Community Groups | Occasional educational visits | Safe and transparent farm | Light outreach and simple tours |

This customer mix keeps Sunrise Acres active in both contract growing and small community markets.

Market Trends

The poultry sector continues to grow as processors, retailers, and households rely on a steady supply of chicken. The trends shaping this environment include:

Strong demand

Chicken sales stay high because processors and retailers use it in a wide range of fresh and processed products.

More controlled-environment houses

Farms are adding better ventilation, cooling, and feeding systems to improve bird health and reduce losses.

Stricter biosecurity and sanitation rules

Integrators expect clear cleanliness, disease control, and accurate records. Houses that meet these standards score higher.

Higher heat-management needs

Georgia summers increase the need for strong airflow, cooling pads, and backup power to protect flock performance.

Steady interest in local farm goods

Customers continue to buy fresh eggs and compost from nearby farms. These sales stay small but steady.

These trends match Sunrise Acres’ plan to run clean, well-ventilated broiler houses with updated equipment.

Competitor Analysis

Sunrise Acres operates in an area where many nearby farms also raise chickens for Pilgrim’s Pride and Claxton Poultry. These farms are the closest direct competitors, but they do not compete for customers, since the company supplies the chicks and controls the schedule. The only comparison between farms comes from the performance ranking, which looks at flock results and affects pay.

Main Competitors

| Competitor | Location | Strengths | Weaknesses |

|---|---|---|---|

| Pilgrim’s Pride Contract Growers | Bulloch County and nearby areas | Experienced operators and strong support routes | Older houses, weaker ventilation, higher fuel use |

| Claxton Poultry Contract Growers | Surrounding counties | Long-term grower base and dependable service | Slower recordkeeping and older house layouts |

| Local Free-Range / Small Farms | Farmers markets in nearby towns | Loyal small customer base | Very small scale, no effect on contract broiler output |

| Compost and Litter Sellers | Local farms and small suppliers | Low-cost compost options | Limited volume and uneven quality |

Sunrise Acres’ Advantage

Sunrise Acres stands out because it combines clean, updated houses with steady daily care and clear records. The farm has strong ventilation, modern equipment, and a backup generator to handle heat and power issues. These strengths support better flock results and consistent performance rankings under the contract system.

For the local community, Sunrise Acres offers fresh eggs, simple pickup, and clean compost at fair prices. This supports local families and growers while adding a small but steady revenue stream.

With its mix of reliable contract work, strong location, and modern equipment, Sunrise Acres is well-positioned in a stable and growing poultry market.

Stop Googling competitors for hours

Product & Services Offered

Sunrise Acres Poultry Farm provides steady broiler production through contract farming and small add-on sales. The farm follows set flock cycles, keeps the houses in good shape, and works under a Pilgrim’s Pride contract that supplies everything needed to raise each group of birds. Extra services like egg sales and compost bring in a small side income and help the local community.

Primary Production Services

Sunrise Acres raises broiler chickens through a structured contract system. Each flock is placed, grown, and picked up on a set schedule, allowing the farm to maintain predictable cycles during the year.

Broiler Production Overview

| Service | Details | Best For |

|---|---|---|

| Broiler Grow-Out Cycle | 4 cycles per year across two houses (40 ft × 500 ft). Each house holds about 21,000 birds. | Contract production for Pilgrim’s Pride |

| Flock Inputs Provided by Company | Chicks, feed, vet support, health checks, pickup schedules, performance-based pay. | Smooth and consistent flock placement |

| Farm Management Duties | House control, temperature and ventilation checks, daily bird care, biosecurity, and recordkeeping. | Reliable production results |

| Expected Live Weight | About 6 lbs per bird at pickup. | Integrator processing requirements |

Annual Output Estimate

| Item | Calculation | Total |

|---|---|---|

| Birds per cycle | 42,000 | — |

| Cycles per year | 4 | — |

| Weight per bird | 6 lbs | — |

| Annual live weight | 42,000 × 4 × 6 | 1,008,000 lbs |

Estimated Contract Earnings

| Item | Amount |

|---|---|

| Pay range per lb | $0.055–$0.065 |

| Revenue per cycle | $55,000–$65,000 |

| Annual gross revenue | $215,000–$255,000 |

Secondary Sales (Direct to Consumer)

Sunrise Acres offers small community-based products that help local residents and nearby farms.

| Product | Details | Price |

|---|---|---|

| Farm-fresh eggs (small flock) | Sold at local farmers’ markets. | $4 per dozen |

| Compost/Litter Sales | Sold to local farms and gardeners for soil enrichment. | $25 per yard |

These small sales serve local customers and make good use of by-products from the farm.

Equipment and Tools

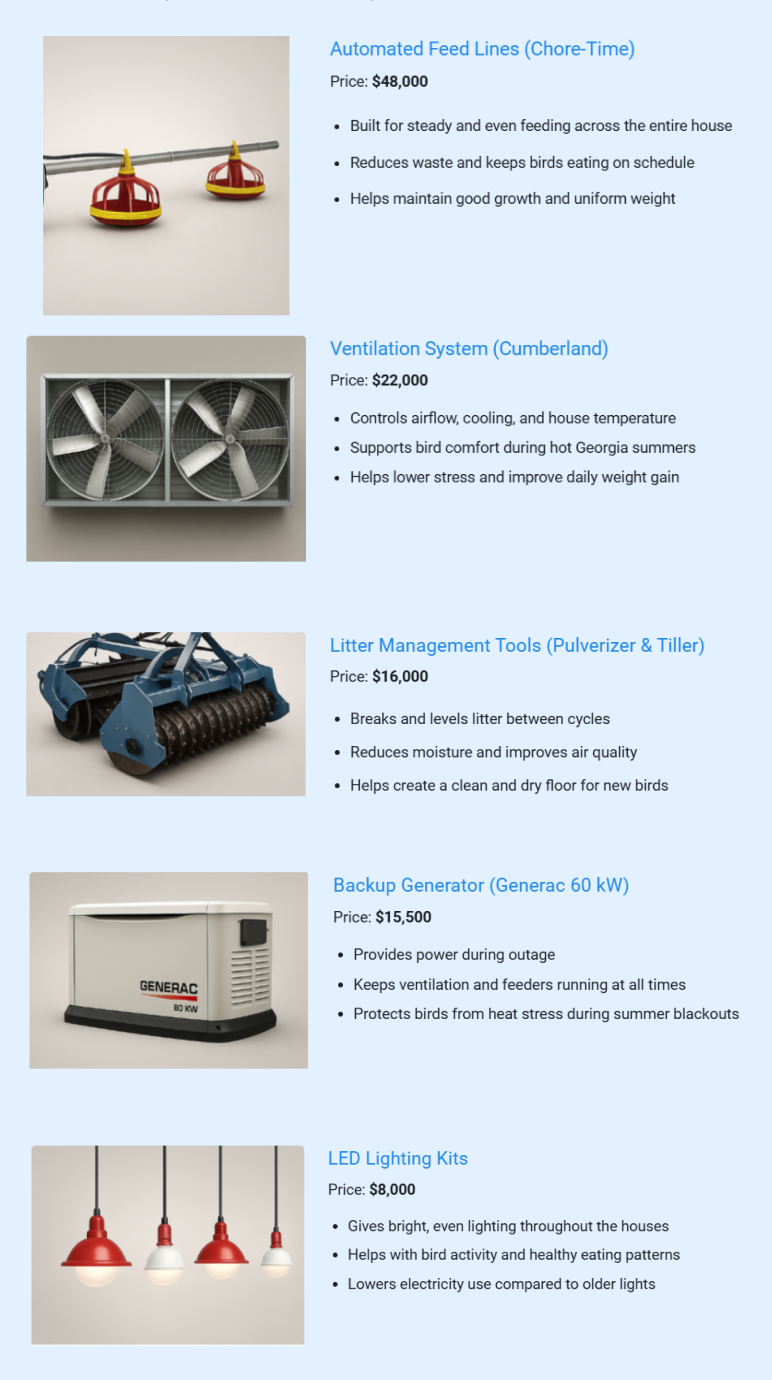

Sunrise Acres uses dependable equipment to keep each flock healthy, maintain steady airflow, and support smooth daily work inside both poultry houses. Every tool listed below is part of the farm’s core setup.

These tools help with simple recordkeeping and daily farm tasks, helping Sunrise Acres stay organized and meet integrator reporting needs.

| Function | Tool / System | Purpose |

|---|---|---|

| Temperature and Ventilation Tracking | House control panels | Monitors airflow, heat, and humidity |

| Flock Records | Integrator-provided forms | Tracks daily conditions and flock progress |

| Power Reliability | Generator monitoring system | Ensures backup power during outages |

| Maintenance Scheduling | Local vendor programs | Keeps equipment serviced on time |

Preferred Farm Service Partners

Sunrise Acres works with trusted partners in the region to keep operations running smoothly during each flock cycle.

Service Partners

- Georgia Poultry Equipment Co.

Helps with repairs, parts, and routine equipment maintenance.

- AgriClean Sanitation Team

Provides deep cleaning at the end of each flock cycle.

- Local Veterinarians (via Pilgrim’s Pride)

Offers health oversight and flock guidance.

- Litter Buyers and Garden Centers

Buy compost and litter for soil improvement.

These partners help the farm stay on schedule and keep each house in good working order.

Operations Plan

Sunrise Acres Poultry Farm runs on a steady daily routine geared toward consistent flock results. The farm follows set grow-out cycles based on the integrator’s schedule. Daily work includes receiving chicks, basic equipment checks, managing airflow and temperature, feeding and watering systems, and monitoring bird health.

Daily operations are based on three principles:

- Consistency in routine – Every day follows the same checks for feed, water, air, and welfare.

- Clean environment – Litter, air flow, and temperature are kept steady to avoid stress.

- Clear records – Temperature logs, flock notes, and biosecurity steps are kept for each cycle.

With Daniel Brooks’ 12 years of broiler house experience, the farm runs on a dependable schedule that supports strong flock performance.

Hours of Operation

The farm operates from 6:00 AM to 7:00 PM each day. During the final weeks of each cycle, the houses are monitored 24/7 because temperature, air flow, and bird behavior can change quickly.

Facility Overview

| Attribute | Specification |

|---|---|

| Location | 8421 Old Orchard Road, Statesboro, GA 30458 |

| Scale | 2 broiler houses (40 ft × 500 ft each) |

| Capacity | About 21,000 birds per house (~42,000 total per cycle) |

| Utilities | Farm power line, backup generator, water line, litter storage area |

| Equipment | Automated feeders, drinker lines, tunnel ventilation system, LED lighting, litter tools |

Workflow System

Sunrise Acres uses a simple three-shift workflow to keep the houses running smoothly.

Daily Cycle

| Stage | Action | Responsible Role | Time |

|---|---|---|---|

| 1. Morning Check | Feed levels, drinker lines, ventilation settings, bird health | Farm Manager / Farm Hand | 6:00–9:00 AM |

| 2. Midday Work | Equipment cleaning, water line flushing, litter work, house adjustments | Farm Hand | 12:00–3:00 PM |

| 3. Evening Check | Temperature check, bird welfare, equipment resets, recordkeeping | Farm Manager | 5:00–7:00 PM |

This routine keeps feed consistent, air flow stable, and flock stress low.

Vendor & Service Contracts

Sunrise Acres works with a set of trusted partners during each flock cycle. Below are the steps these partners handle:

Step 1: Chick placement and flock guidance

Pilgrim’s Pride supplies the chicks, feed, flock health guidance, and pickup schedule.

Step 2: Equipment service and repairs

Georgia Poultry Equipment Co. handles equipment checks, repairs, and service needs.

Step 3: Power and meter assistance

Georgia Power provides the agricultural power program and meter help when required.

Step 4: Deep cleaning after each cycle

AgriClean completes the per-cycle deep cleaning and sanitation work.

These steps help keep the houses ready and steady for every new flock.

Safety & Compliance Plan

The farm follows all required rules for poultry care, farm safety, and environmental standards. This includes meeting USDA Animal Welfare Certification, the Georgia Poultry Farm Permit, and integrator care requirements.

Biosecurity practices such as foot baths, logbook entries, controlled entry, clean clothing, and visitor sign-ins are used every cycle. Litter is managed under Georgia waste rules, stored safely, and sent to local farms, with full clean-outs handled by AgriClean.

Routine farm safety checks cover wiring, heaters, fans, and equipment, along with generator testing and clear walkways. These combined steps protect the birds and help keep the operation in good standing.

Quality Control System

Each flock goes through a repeatable set of checks to keep the farm consistent. Below is the checklist we follow for every flock:

These steps help Sunrise Acres maintain clean houses, stable conditions, and strong performance across every cycle.

Investors hate amateur writing errors

Instantly improve your plan w/ our AI writing assistant

Milestones and Timeline

Sunrise Acres has a clear schedule for upgrades, flock placement, and stable operation.

| Milestone | Timeline | What It Means |

|---|---|---|

| LLC Formation | January 2026 | Business officially registered in Georgia |

| USDA Loan Submission | January 2026 | Application for operating and equipment funding |

| Farm Upgrades | April 2026 | Install ventilation, feeders, lighting, and generator |

| Integrator Contract Finalized | May 2026 | Agreement for chick placement and pickup cycles |

| First Chick Delivery | June 2026 | Start of the first grow-out cycle |

| First Harvest Cycle | August 2026 | Initial full flock completed |

| Break-even Target | Q1 2027 | Reaching enough production to cover all operating costs |

Marketing & Sales Strategy

Sunrise Acres uses a simple and steady marketing approach built around its contract with Pilgrim’s Pride and small local sales. The main focus is to keep production cycles smooth, maintain a trusted name in the community, and grow small direct-to-consumer sales over time. The farm uses local events, online updates, and clear communication to stay connected with buyers and families in Bulloch County.

Marketing Channels and Budget

Most income comes from the integrator contract, so the farm does not need a large marketing budget. The small local sales program is handled through nearby markets, basic promotions, and online pages that show farm life and daily work.

| Channel | Percentage | Monthly Budget ($) | Annual Budget ($) | Description |

|---|---|---|---|---|

| Local Farmers Markets | 40% | $160 | $1,920 | Builds small egg sales in Statesboro and Brooklet. |

| Social Media (Facebook, Instagram) | 25% | $100 | $1,200 | Shares farm updates, flock milestones, and educational posts. |

| Community Events | 20% | $80 | $960 | Helps with school visits and “Know Your Farmer” days. |

| Flyers & Local Groups | 10% | $40 | $480 | Simple flyers shared through farm groups and garden clubs. |

| Website Upkeep | 5% | $20 | $240 | Keeps basic farm info and contact details online. |

| Total | 100% | $400 | $4,800 | — |

Customer Acquisition Plan

Sunrise Acres plans to grow its small direct-to-consumer sales through steady community engagement each year. In the first year, the focus is on building trust at local farmers’ markets, starting a 20-family egg subscription, and selling compost and litter to nearby gardeners.

In the second year, the farm aims to expand the egg subscription to around 50 families, join additional markets, and increase the list of compost buyers.

By the third year, the plan is to explore a small on-farm pickup area, offer educational farm days twice a year, and strengthen repeat buyers through consistent quality and clear communication. The goal is to stay visible, keep a simple routine, and build long-term relationships in the community.

Referral & Promotion Programs

Sunrise Acres uses small and honest promotions that help build local goodwill and encourage families to choose the farm.

| Program | Offer / Mechanism | Purpose |

|---|---|---|

| Egg Subscription Discount | $2 off per dozen for monthly subscribers | Build regular buyers |

| Market Loyalty Card | Buy 5 dozen, get 1 dozen free | Encourage return visits |

| School Tour Days | Free tours for local schools | Community connection |

| Litter Buyer Discount | $5 off per yard for bulk buyers | Help local farms |

| Social Media Shoutout | Simple thank-you post for repeat buyers | Build engagement |

These small efforts help the farm stay rooted in the community.

Sales Channels

Sunrise Acres sells through two simple channels:

- Pilgrim’s Pride Contract (Primary)

- 100% of broiler production goes to the integrator

- Birds, feed, vet care, and pickups managed through contract

- Provides a steady income and predictable work

- Direct-to-Consumer (Secondary)

- Eggs sold at local farmers’ markets

- Litter and compost sold to gardeners and local farms

- Social media used for simple updates

- Egg subscription program for families

This mix keeps the business stable while building a small local presence.

Staffing Plan

A small team handles farm work, bird care, and farm-to-market tasks. Each role handles both production and small direct sales.

| Position | Annual Pay | Details |

|---|---|---|

| Daniel Brooks (Farm Manager) | $50,000 | Runs daily farm work and manages broiler cycles. |

| Hannah Brooks (Admin/Compliance) | $32,000 | Handles records, permits, and local sales tracking. |

| Part-Time Farm Hand | ~$22,000 | Helps with cleaning, litter work, and market prep. |

| Veterinarian (Contract) | $4,500 | Oversees flock checks and health needs. |

| Total Estimated Payroll | $108,500 | — |

Shift Structure

Daily work at Sunrise Acres follows a steady routine to keep each broiler cycle running on time. Mornings are spent checking feed levels, adjusting ventilation, and reviewing bird health.

Midday work focuses on cleaning equipment, flushing water lines, and managing litter inside the houses. In the evenings, the team handles. welfare checks, temperature control, and updating daily logs.

This routine keeps the houses stable throughout the day and meets both contract requirements and the farm’s small local sales activities.

Risk and Mitigation

Every farm faces certain risks, and Sunrise Acres has clear steps in place to manage them.

- Disease Outbreak

Risk: Poultry farms can face disease issues that spread quickly and affect the whole group of birds. This can lead to losses, missed cycles, and delays in revenue.

Mitigation: Sunrise Acres follows strict biosecurity, limits entry into the houses, and works closely with the integrator’s veterinarian. Regular checks, clean surroundings, and controlled access help keep the birds safe.

- Power Failure

Risk: Broiler houses depend on steady power for ventilation, cooling, and feeding. A power loss can cause heat buildup, stress, and bird deaths.

Mitigation: The farm uses a 60 kW backup generator and checks it weekly to make sure it starts fast when needed. This keeps airflow and temperature under control even during outages.

- Market Price Changes

Risk: Poultry prices can shift in the wider market, which can make income uncertain for many farms.

Mitigation: Sunrise Acres is protected by the contract system with Pilgrim’s Pride. The integrator pays a set rate per pound based on performance, so the farm does not carry the risk of changing retail prices.

- Extreme Heat in Summer

Risk: Georgia summers can cause high heat inside the houses. Without proper cooling, birds may suffer stress or slow growth.

Mitigation: The farm uses tunnel ventilation, strong cooling fans, and misting systems to keep the houses at safe temperatures. These upgrades help maintain steady airflow and protect birds during hot months.

With these steps, Sunrise Acres can manage common challenges and keep the farm running steadily year-round.

Don’t spend weeks on your first draft

Complete your business plan in less than an hour

Financial Plan

Sunrise Acres Poultry Farm is built on a stable contract model with predictable cycles and clear operating costs. The farm will launch with a total startup investment of $250,000, funded by a $480,000 USDA Farm Operating + Equipment Loan package and $130,000 in owner equity.

The goal is to reach break-even within the first full year of production and move into steady profit by Year 2.

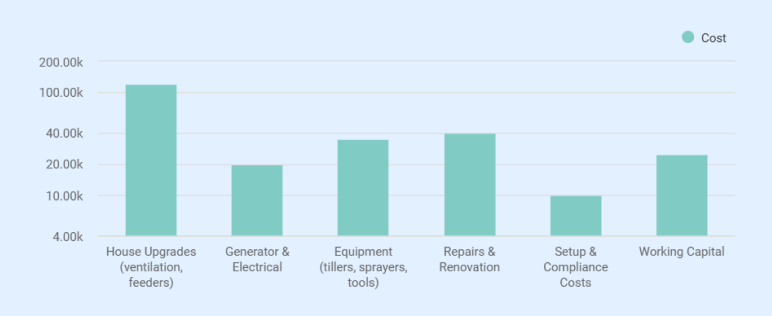

Startup Costs

Sunrise Acres will require about $250,000 to begin operations. This covers upgrades to the poultry houses, essential equipment, permits, and working capital for early cycles.

| Category | Cost | Notes |

|---|---|---|

| House Upgrades (ventilation, feeders) | $120,000 | Required for contract standards |

| Generator & Electrical | $20,000 | Backup power |

| Equipment (tillers, sprayers, tools) | $35,000 | Core farm equipment |

| Repairs & Renovation | $40,000 | Structural work + insulation |

| Setup & Compliance Costs | $10,000 | Permits, vet checks |

| Working Capital | $25,000 | Covers 2 grow-out cycles |

| Total Startup Investment | $250,000 | Part of $480k USDA loan |

Key Assumptions

These assumptions shape the 3-year plan.

| Assumption | Details |

|---|---|

| Birds per Cycle | 42,000 |

| Cycles per Year | 4 |

| Integrator Contract | Pilgrim’s Pride |

| Pay Rate | $0.055 to $0.065 per lb live weight |

| Avg Live Weight | 6 lbs |

| Annual Output | 1,008,000 lbs |

| Utilities | $48,000 per year |

| Litter & Disposal | $12,000 |

| Vet Services | $6,000 |

| Fuel | $7,000 |

| Repairs | $10,000 |

| Loan Interest Rate | 4.25% fixed |

| Break-even | About $18,000 per month (~1 full cycle) |

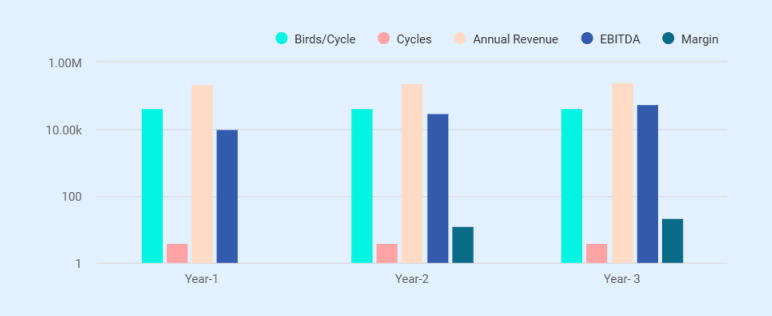

Revenue Forecast

This forecast is based on four cycles per year and performance-based earnings.

| Year | Birds/Cycle | Cycles | Annual Revenue | EBITDA | Margin |

|---|---|---|---|---|---|

| Year 1 | 42,000 | 4 | $225,000 | – $10,000 (setup year) | -4% |

| Year 2 | 42,000 | 4 | $235,000 | + $30,000 | 13% |

| Year 3 | 42,000 | 4 | $250,000 | + $55,000 | 22% |

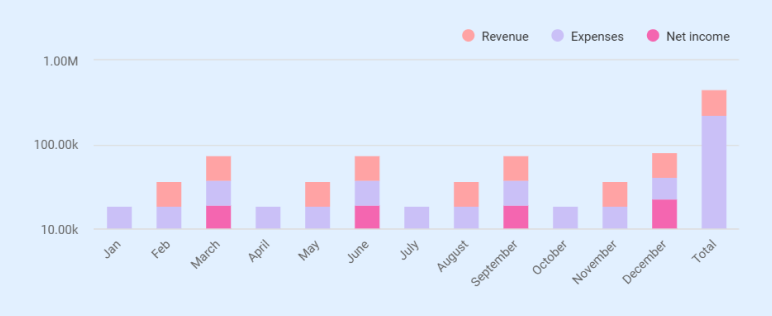

Monthly Projections (Year 1)

This table shows the expected monthly revenue and expenses for Year 1 based on four broiler cycles.

| Month | Cycle Activity | Revenue | Expenses | Net Income |

|---|---|---|---|---|

| Jan | Cycle 1 prep | $0 | $18,500 | -$18,500 |

| Feb | Grow-out | $18,000 | $18,500 | -$500 |

| Mar | Harvest + downtime | $37,500 | $18,500 | +$19,000 |

| Apr | Cycle 2 prep | $0 | $18,500 | -$18,500 |

| May | Grow-out | $18,000 | $18,500 | -$500 |

| Jun | Harvest + downtime | $37,500 | $18,500 | +$19,000 |

| Jul | Cycle 3 prep | $0 | $18,500 | -$18,500 |

| Aug | Grow-out | $18,000 | $18,500 | -$500 |

| Sep | Harvest + downtime | $37,500 | $18,500 | +$19,000 |

| Oct | Cycle 4 prep | $0 | $18,500 | -$18,500 |

| Nov | Grow-out | $18,000 | $18,500 | -$500 |

| Dec | Final harvest | $41,000 | $18,500 | +$22,500 |

| Total | — | $225,000 | $222,000 | -$10,000 |

Projected Profit & Loss (3 Years)

| Category | Year 1 | Year 2 | Year 3 |

|---|---|---|---|

| Revenue | $225,000 | $235,000 | $250,000 |

| Operating Expenses | |||

| Electricity | $30,000 | $30,000 | $30,000 |

| Gas / Heating | $8,000 | $8,000 | $8,000 |

| Water Usage | $10,000 | $10,000 | $10,000 |

| Total Utilities | $48,000 | $48,000 | $48,000 |

| Supplies | |||

| Litter (per flock cycles) | $12,000 | $12,000 | $12,000 |

| Vet visits | $4,000 | $4,000 | $4,000 |

| Medications | $2,000 | $2,000 | $2,000 |

| Total Vet + Litter | $18,000 | $18,000 | $18,000 |

| Routine Operations | |||

| Fuel (farm use) | $7,000 | $7,000 | $7,000 |

| Tools & repair parts | $6,000 | $6,000 | $6,000 |

| Emergency repairs | $4,000 | $4,000 | $4,000 |

| Total Fuel + Repairs | $17,000 | $17,000 | $17,000 |

| Other Operating Costs | |||

| Labor (family + hired help) | $78,000 | $60,000 | $55,000 |

| Insurance | $12,000 | $12,000 | $12,000 |

| Loan payments | $40,000 | $30,000 | $25,000 |

| House upkeep & cleaning | $22,000 | $20,000 | $20,000 |

| Total “Other Costs” | $152,000 | $122,000 | $112,000 |

| Total Expenses | $235,000 | $205,000 | $195,000 |

| Net Result | -$10,000 | +$30,000 | +$55,000 |

Projected Cash Flow (3 Years) Break-Even Analysis

| Category | Year 1 | Year 2 | Year 3 |

|---|---|---|---|

| Cash Inflow (Revenue) | $225,000 | $235,000 | $250,000 |

| Cash Outflow (Operating Costs) | -$235,000 | -$205,000 | -$195,000 |

| Net Cash from Operations | -$10,000 | +$30,000 | +$55,000 |

| Loan Proceeds | $480,000 | — | — |

| Owner Equity | $130,000 | — | — |

| Loan Repayment | -$45,000 | -$45,000 | -$45,000 |

| Equipment & Upgrades | -$250,000 | — | — |

| Net Cash Flow | $305,000 | -$15,000 | +$10,000 |

| Opening Cash Balance | $0 | $305,000 | $290,000 |

| Ending Cash Balance | $305,000 | $290,000 | $300,000 |

- Monthly operating cost: about $18,500

- Average revenue per cycle (Year 1): ~$55,000

- Cycles per year: 4

Break-even

≈ $18,000 per month, equal to one full grow-out cycle.

Funding Request & Repayment Plan

Sunrise Acres is requesting a USDA Farm Operating + Equipment Loan totaling $480,000.

Funds will be used for

- Upgrading both poultry houses

- New ventilation and feeding systems

- Generator and electrical work

- Required compliance upgrades

- Tools and equipment

- Early operating capital for the first two cycles

Loan Terms

- 12-year operating loan and 7-year equipment loan

- 4.25 percent fixed interest

- Backed by poultry houses, equipment, and land improvements

Owner Contribution

Daniel and Hannah Brooks are contributing $130,000 through land value, cash, and existing small flock assets.

The farm expects to reach break-even within one year and produce stable profits by Year 2, allowing smooth repayment across the loan term.

The Quickest Way to turn a Business Idea into a Business Plan

Fill-in-the-blanks and automatic financials make it easy.