Executive Summary

TimberForge Custom Woodcraft, LLC is a one-owner woodworking shop in Grants Pass, Oregon, specializing in custom furniture, built-ins, cabinetry, and CNC-machined parts. The workflow is designed for the output that one skilled craftsman can manage, with the focus on precision, consistent turnaround times, and clear communication rather than high-volume production.

The workshop is a combination of CAD-based design, CNC precision with traditional joinery, and the owner is able to undertake a broader scope of projects as compared to a one-person shop. Such a combination makes less work for the hands and increases the productive potential without affecting the quality of the crafts.

Local Market Conditions

Two forces that support the demand for small and mid-size woodwork in the Grants Pass-Medford corridor include:

Home turnover and renovation cycles

Many buyers update interiors within the first 12–18 months of ownership. Items most often replaced include cabinets, shelving, tables, and storage built-ins.

Limited supply of reliable custom shops

Larger millwork firms in the area lean toward commercial-grade cabinetry or long-lead kitchen jobs.

The Grants Pass long-term housing projections refer to over 4000 new residential units in the urban expansion plan. Even a small share of these homes requiring custom shelving, vanity builds, cabinetry upgrades, or CNC-cut parts is enough to sustain steady work for a niche woodworking shop. This level of ongoing renovation and build-out activity supports a consistent project pipeline.

Customers Served

TimberForge works with three consistent customer groups:

| Segment | What They Buy | Why They Don’t Go to Retail |

|---|---|---|

| Homeowners | Tables, cabinets, built-ins, shelves | Retail sizing rarely fits; they want better woods, tighter joinery, and the ability to choose finish and dimensions |

| Remodelers & contractors | Vanities, shelving sets, CNC components, stair parts | Need precise cuts, fitting accuracy, and predictable timing; avoid cabinet factories with long queue times |

| Small local businesses | Counters, signage, and display stands | Need one-off sizing, hardwood durability, and branding elements |

Owner & Management

The shop is owned by Owen Mathers, whose background spans cabinetry, precision finishing, remodeling workflow, and CAD/CNC production. This combination lets him:

- Quote accurately and prevent margin loss

- Produce detailed 3D designs that reduce revision cycles

- Deliver repeatable CNC components for contractors

- Uphold a level of finishing that sets handmade pieces apart from factory builds

In Year 2, a part-time assistant supports milling, sanding, and assembly, which relieves bottlenecks and raises monthly output.

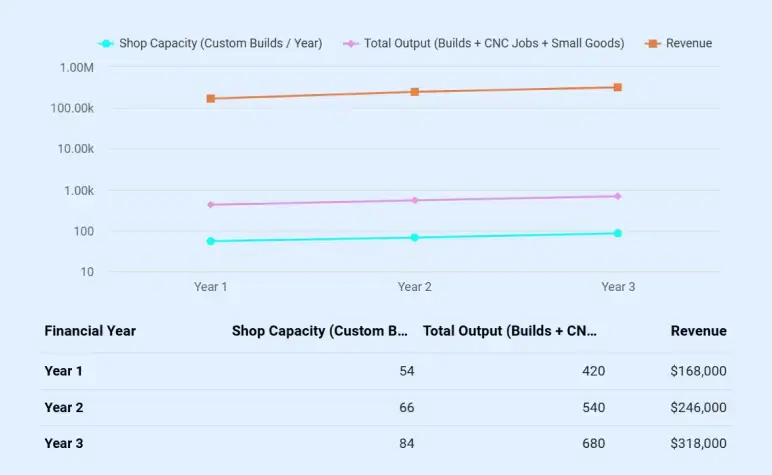

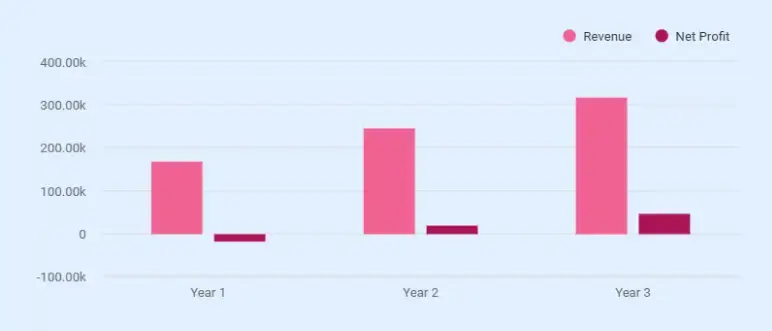

Financial Outlook

The success of the financial flow indicates an increase in efficiency, better timing of the projects, and retention of the contractors.

| Year | Revenue | Net Income | How the Business Gets There |

|---|---|---|---|

| 1 | 168,000 | –18,000 | Brand building, inconsistent early bookings, owner absorbing most labor |

| 2 | 246,000 | 20,000 | Throughput increases with assistance; fewer time gaps between projects |

| 3 | 318,000 | 48,000 | Higher contractor repeat work, more predictable scheduling, and reduced downtime |

The shop breaks even in Year 2, but by Year 3, it reaches sustainable profitability with greater throughput monthly and more stability in workflow.

Startup Funding

The funding would not only cover equipment but also the construction of the space to ensure that it becomes functional and compliant with continued production.

| Source | Amount |

|---|---|

| Equipment Loan (Rogue River CCU) | $68,000 |

| Owner Equity | $42,000 |

| Total Funding | $110,000 |

This capital covers CNC equipment, machine tools, dust-collection systems, electrical upgrades, lumber inventory, and sufficient working capital to get the shop operating until revenue is stable.

Business Overview

Land and Property Details

TimberForge Custom Woodcraft operates from a rented workshop in a light-industrial area of Grants Pass, Oregon. The location offers convenient access to lumber suppliers, active contractor networks, and surrounding residential neighborhoods that support demand for custom woodworking.

The space is organized to accommodate CNC production, hand-tool work, finishing, storage, and client consultations within an efficient layout.

| Category | Details |

|---|---|

| Address | 1448 SE M Street, Unit B, Grants Pass, Oregon |

| Zoning | Light-industrial |

| Access | Close to lumber suppliers, contractors, and residential areas |

| Production Areas | CNC and machine floor, finishing room, lumber, and sheet-goods storage |

| Client Areas | Small office with samples, finishes, and display pieces |

| Logistics | Rear roll-up door and parking for deliveries, trailers, and customer pickups |

| Utilities | Connected to city power, water, and waste services |

| Build-Out Work | Electrical upgrades, dust-collection installation, and ventilation improvements |

| Compliance | Meets OSHA safety expectations and insurance requirements |

| Lease Terms | Fully insured space with renewal options for long-term operations |

Legal & Operating Framework

TimberForge is registered as an LLC in Oregon, which is the state that provides the owner with the maximum control of the business and segregates the personal and business liability. The workshop is housed in a light-industrial unit equipped for machine milling, finishing, and CNC operations. The space is chosen specifically for:

- Proximity to hardwood suppliers

- Access to tradespeople who require steady CNC fabrication

- Noise-tolerant zoning

- Sufficient electrical infrastructure for dust extraction and machine loads

Operations begin once electrical upgrades, dust-collection installation, and ventilation improvements are complete.

How TimberForge Works

Unlike cabinetry factories or mass furniture producers, TimberForge operates around job sequencing, not batch manufacturing. The workflow is designed for a one-person shop trying to maintain consistent earnings without creating production bottlenecks.

| Stage | What Happens | Why It Matters |

|---|---|---|

| Intake & Design | Clients share measurements and reference photos; CAD layouts are drafted. | Filters unrealistic requests early and reduces rework. |

| Material Planning | Hardwoods chosen for stability and grain; sheet goods broken down via CNC. | Improves yield, reduces waste, and supports precise joinery. |

| Milling & CNC Work | CNC handles repetitive cuts, mortises, templates, and panel machining. | Lowers labor time and prevents accuracy-related errors. |

| Bench Work & Assembly | Joinery, glue-ups, hardware fitting, and adjustments are completed by hand. | Ensures fit and finish meet project standards before coating. |

| Finishing | Oil or water-based systems applied in a controlled, dust-isolated room. | Consistent curing and surface quality without contamination. |

| Delivery or Installation | Final pieces delivered or installed with an on-site partner. | Ensures proper leveling, fastening, and long-term durability. |

This approach keeps scheduling predictable and allows multiple revenue types to overlap smoothly.

How TimberForge Differentiates Itself

Most small woodworking shops in the region either:

- Produce only furniture

- Produce only cabinetry

- Operate as hobby shops with inconsistent capacity

TimberForge sits in a distinct middle category:

- It can handle precise CNC-cut parts like a millwork shop

- It can produce hand-finished, solid hardwood builds like a furniture studio

- It has a fast enough turnaround to meet remodel timelines

- It focuses on mid-size work that larger shops avoid due to low margins

This gives TimberForge access to projects that are too detailed for factories and too time-consuming for hobbyists.

Supply Chain & Technical Support

TimberForge will work with established suppliers and service partners to keep production consistent and compliant:

- South Coast Lumber Co. distributes hardwoods like myrtlewood, maple, and walnut, which are used in the majority of custom construction

- Häfele America is a supplier of hinges, slides, and cabinet hardware in cabinetry and built-in projects

- Rockler Woodworking & Hardware supplies specialty fittings, jigs, and hardware that are applied to small-scale items and custom orders

- Osmo Polyx-Oil products are applied to give a durable and natural finish to tables, interior furniture

- General Finishes sells water-based and oil-based finishes on cabinets, built-ins, and refinishing projects

- Axiom Precision offers technical support, guidance on calibration, as well as service resources to the CNC router of the shop

- SawStop provides parts and technical support for the shop’s table saw safety system

- A local CPA will manage bookkeeping, sales tax records, and lender reporting, with support from state-verified professionals.

These partners give TimberForge access to dependable materials, safety-focused equipment support, and accurate financial oversight while allowing the owner to focus on design, production, and client work.

Market Research

Custom woodwork remains in steady demand across the country. Homeowners are seeking furniture, built in and cabinetry that is of higher quality than what is available in big box shops. Contractors should also have reliable shops in terms of vanities, shelving, CNC-cutting parts, and specialty fabrication. These are the needs that make the woodworking industry busy in the big cities and in the smaller communities throughout the state of Oregon.

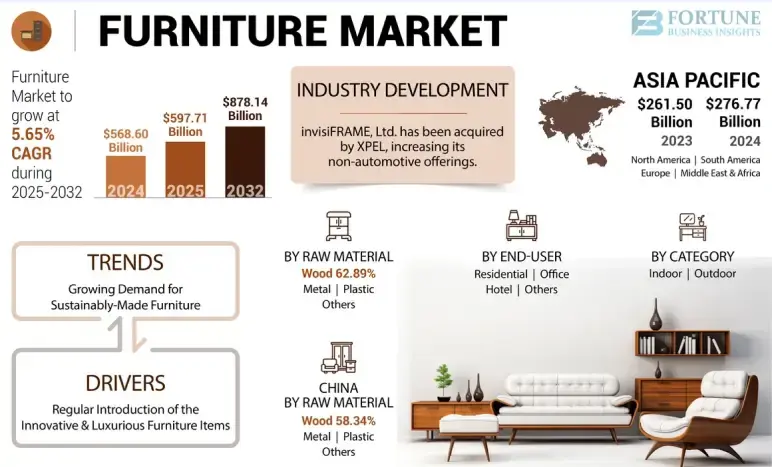

Industry data shows the global furniture market was valued at $568.6 billion in 2024 and is projected to reach $878.1 billion by 2032, driven by growing demand for home improvement and custom furniture. Demand trends favor solid-wood, made-to-order, and locally produced items; an opportunity that aligns well with TimberForge’s custom-woodwork focus.

United States Market

The woodworking/home-upgrade business in the United States is maintained by a good remodeling business and consistent interior upgrades in new and old residential homes. The trend has been stable because people are renovating their homes and changing old-fashioned cabinets, redesigning their rooms in new designs, and even investing their money in durable furniture that would suit their places well compared to factory-manufactured furniture.

Oregon Market

Oregon has a rich history of woodworking and an already existing network of hardwood mills, which is beneficial to maintain a healthy supply chain of small and mid-scale shops.

The Grants Pass and Rogue Valley are also experiencing constant remodeling, as evidenced by the stable sales of homes and the continued development of houses. The 20-year housing forecast of the area promises over 4,000 new houses, indicating the need for long-term availability of the cabinetry, built-ins, and interior woodworking.

In Josephine and Jackson Counties, local contractors are working with remodeled pipelines with understated durations of several weeks, which presents a predictable demand for precise and rapid-turnaround production.

Market Trends

- Made-to-order furniture

More buyers want pieces built specifically for their space, including dining tables, vanities, shelves, and full built-ins.

- CNC-supported fabrication

Contractors increasingly seek CNC-cut parts for precision and speed, making CNC-capable shops stand out in smaller markets.

- Local, small-batch goods

Items such as cutting boards, trays, and shelves sell well at craft fairs and online platforms, providing steady supplemental revenue.

- Shorter lead times

Large shops often book out 6–10 weeks. A shop offering consistent 3–5-week turnarounds becomes a strong option for both homeowners and contractors.

Target Market Segments

| Segment | Who They Are | What They Need | TimberForge Helps |

|---|---|---|---|

| Homeowners | Ages 30–65, remodelers, new buyers | Custom furniture, cabinets, and built-ins | Local craftsmanship, clear design sessions, solid wood builds |

| Contractors & Remodelers | Builders, installers, trades | Vanities, shelving, CNC parts, fast turnarounds | Reliable fabrication, 3–5 week timing, accurate CNC cutting |

| Small Businesses | Cafes, shops, offices | Counters, displays, signage | One-off builds, custom sizing, durable materials |

| Local Craft Buyers | Shoppers at markets/Etsy | Cutting boards, trays, and shelves | Small-batch items, gift-ready pieces |

Competitive Landscape

The Southern Oregon woodworking market is composed of a combination of both established cabinetry shops, mid-sized millwork companies, and smaller independent manufacturers. All these groups are a portion of the demand, but none of them is the entire gamut of custom furniture, CNC fabrication, and short-lead-time builds that TimberForge offers.

Established Cabinet & Millwork Shops

Pacific Coast Millworks (Grants Pass)

One of the most famous millwork shops with large remodels, commercial jobs, and volumes of cabinetry. They are strong in their capacity because much of their workload is booked weeks before, and as a result, the homeowners and contractors experience long turnaround periods. Another point is that they do not target primarily mixed furniture-plus-built-ins, but they are more cabinetry-oriented.

Rogue Valley Cabinets (Medford)

A mid-size cabinet producer serving Josephine and Jackson Counties. Their workflow is built around standardized and semi-custom cabinets. They are reliable for kitchen and vanity work, but not ideal for one-off furniture, custom sizing, or projects requiring detailed design collaboration.

Independent Small Makers

Some local woodworkers are part-time or hobbyists who market their output on Etsy or in small local workshops. These designers tend to sell cutting boards, shelves, and minor pieces of occasional furniture. They are appealing in terms of pricing, but not capacity, and rarely accept multi-piece custom jobs or contractor-constructed jobs with deadlines.

Stop searching the internet for industry & market data

Get AI to bring curated insights to your workspace

Service Offerings

TimberForge Custom Woodcraft offers a specialized variety of woodworking and fabrication services to individuals, contractors, and other small, local enterprises. The shop combines CNC precision with hand-worked craftsmanship to achieve custom work on a reliable schedule.

Our Services

These are the primary services customers request and the foundation of TimberForge’s workload.

Each project includes a clear estimate, a 3D design mockup when needed, and final approval before production begins.

Small-Batch & Retail Goods

These items help fill the production schedule and generate consistent monthly revenue.

| Product Type | Price Range | Notes |

|---|---|---|

| Cutting Boards | USD 55–115 | Hardwood boards, end-grain options |

| Serving Trays | USD 65–140 | Walnut, maple, mixed hardwood |

| Live-Edge Shelves | USD 95–280 | Sourced from local mills |

| Gift Items | USD 25–75 | Coasters, small décor, seasonal craft-fair pieces |

Contractor & Trade Services

Local contractors depend on reliable fabrication for remodels, upgrades, and tight project deadlines.

| Contractor Service | Billing Model | Typical Use |

|---|---|---|

| CNC Part Fabrication | Hourly or per-piece | Cabinet parts, templates, repeat components |

| Built-In Fabrication | Per project | Vanities, mudroom units, shelving systems |

| Assembly-Ready Components | Per piece | Prefit parts for installers |

| On-Site Installation | Hourly | Final fit, trim, alignment |

Contractor work provides consistent volume and predictable month-to-month revenue.

Specialized & Add-On Services

These offerings increase margins and help keep production steady throughout the year.

| Service | Typical Price | Role |

|---|---|---|

| 3D Design Consultation | USD 75 flat fee | Helps clients visualize projects |

| Finish Upgrades | Varies | Premium oils, stains, and protective coats |

| Material Sourcing | At cost + markup | Local hardwoods through South Coast Lumber |

| Custom Engraving | Included in CNC | Signs, logos, personalized projects |

Contractor work provides consistent volume and predictable month-to-month revenue.

Vendor & Supply Chain Management

TimberForge works with reliable suppliers who provide hardwood, hardware, and finishes throughout the year. South Coast Lumber Co. supplies the shop with locally sourced maple, walnut, and myrtlewood, giving the owner consistent access to quality lumber with stable grain and dependable availability.

Haefele America provides hinges, slides, and cabinet hardware for built-in and cabinetry work. Rockler Woodworking and Hardware offers specialty fittings, jigs, clamps, and small hardware required in custom and one-off work.

Osmo Polyx-Oil and General Finishes supply the wood finishes used in the shop. Both offer durable, reliable coating systems suitable for furniture and cabinetry. Axiom Precision and SawStop also provide continuous maintenance services to the CNC router and the table saw, which maintain equipment accuracy and safety.

Working with multiple vendors reduces delays, maintains stock reliability, and helps control project costs. Lumber, hardware, and finishing materials are tracked through simple project logs so each build remains accurate and on budget.

Customer Experience Add-Ons

TimberForge includes several add-ons that make the custom woodworking process clear, simple, and supportive for customers.

- 3D project mockups: Visual designs sent before production for review and approval.

- Progress updates: Photos of key build stages for longer projects.

- Delivery and installation: Available for qualifying furniture and built-ins.

- Material and finish samples: In-shop selection for color, texture, and style.

- Gift-ready packaging: Available on small-batch goods such as cutting boards and trays.

- Seasonal workshops: Occasional sessions on wood care, finishes, and basic maintenance.

These extras help customers understand the process, feel involved in the build, and trust the shop’s craftsmanship.

Marketing & Sales Approach

TimberForge is based on an intensive marketing and sales approach that is feasible for a one-owner woodworking business. Both channels are selected based on the fact that they are cheap, produce a flow of leads, and can appeal to homeowners and contractors who request to have custom woodwork.

Local Discovery & Search Visibility

Homeowners typically find TimberForge when searching for local cabinet makers, custom furniture builders, or CNC services. The Google Business Profile is the shop’s primary discovery tool because it displays recent projects, reviews, and updated contact details. Keeping this profile active ensures consistent organic inquiries with no advertising spend.

Social Media Presence

On Instagram and TikTok, short build clips, before and after shots, and finishing work are shared. This aids the customers to experience the shop in terms of quality workmanship without giving an entire explanation.

| Platform | Use |

|---|---|

| Finished pieces, reels, progress photos | |

| TikTok | Quick build clips and tool work |

Contractor Partnerships

Contractors offer recurring work such as shelving sets, vanities, and CNC-cut components. These projects help stabilize income between homeowner builds.

| Type of Work | What TimberForge Provides |

|---|---|

| Remodel projects | Vanities, built-ins, shelving |

| CNC components | Accurate, ready-to-install parts |

| Short-deadline jobs | Quicker turnaround than larger shops |

Small-Batch Goods & Local Markets

Small-scale products such as cutting boards and trays are retailed at infrequent artisan markets. These are sent to new homeowners, and they act as additional income during slack months.

| Item Type | Sales Channel |

|---|---|

| Boards, trays | Craft markets |

| Small shelves | Local pickup |

| Gift items | Seasonal events |

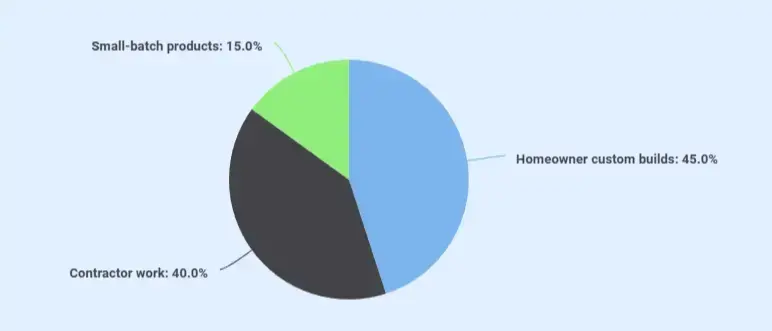

Expected Work Mix

The shop maintains a balanced mix of homeowners, contractors, and small-batch sales.

Operations Plan

TimberForge Custom Woodcraft runs as a project-based woodworking shop with a steady workflow of custom builds, cabinetry, CNC jobs, and small-batch items. The goal is to keep production predictable, maintain quality, and protect cash flow.

Core Operating Approach

- Workflow sequence

Projects follow a fixed path:

Design → material selection → CNC milling → assembly → finishing → delivery.

This structure keeps lead times within the typical 3–5 week range.

- Quality control

Each job is checked for accurate dimensions, joinery fit, sanding quality, and finish consistency. CNC work is paired with hand-finishing to maintain a consistent standard.

- Material and cost control

Materials are ordered per project and tracked against estimates. Deposits cover material costs, and final costs are reviewed before delivery to stabilize cash flow.

The owner oversees design, production, client communication, and scheduling. CNC-only jobs and small-item production fill open blocks in the calendar to keep the shop active between larger builds.

Hours of Operation

The shop operates on a production-focused schedule designed to finish work consistently while giving clients predictable communication windows.

| Day | Hours | Notes |

|---|---|---|

| Mon–Fri | 8:00 AM to 5:00 PM | Full production + customer calls |

| Saturday | By appointment | Installations, design meetings, pickups |

| Sunday | Closed | — |

Finish curing, which often takes 24–72 hours, is planned into the weekly cycle so jobs don’t get stuck in the final stage.

Facility Overview

The workshop is a light-industrial unit arranged to move lumber efficiently from delivery to finished output. The layout avoids backtracking and reduces dust transfer between areas.

| Zone | Function | Notes |

|---|---|---|

| CNC & Machine Floor | Milling sheet goods and hardwood | Near rear roll-up door for fast handling |

| Assembly Area | Joinery, glue-ups, fitting | Central location for quick movement from the CNC |

| Finishing Room | Staining, oiling, curing | Isolated and ventilated to keep dust out |

| Office & Client Area | Design reviews, material samples | Quiet front space separate from production |

Electrical upgrades, dust-collection lines, and ventilation improvements support safe milling and finishing, and reduce cleanup time.

Layout Efficiency

The workshop is designed to restrict the volume of material movement, bottlenecks, and to have a straightforward flow of raw lumber to a finished product. The location of every zone within the shop has a distinct operation objective, which enables TimberForge to maintain the lead times and predictability in production.

Material Flow Efficiency

Raw lumber and sheet goods can be brought in through the rear roll-up door and into the CNC machine and machine area. This saves on the occurrence of double handling, and milling can commence as soon as delivery is made.

Straight-Line Production Path

After milling, the milled parts pass to the central assembly area, where joinery, glue-ups, and hardware fitting are done. This linear route will do away with such unnecessary movement of heavy parts.

Dust and Noise Separation

CNC routing and machine milling generate the most noise and dust, so these functions are located away from the finishing room and client area to maintain clean surfaces and safe working conditions.

Dedicated Finishing Zone

The finishing area is isolated and ventilated to protect workers from airborne dust and ensure consistent curing times. This prevents rework and maintains quality standards.

Compact Office and Client Zone

The front office provides a quiet space for estimates, 3D design reviews, and material selection. Keeping client activity away from the production floor improves safety and avoids workflow interruptions.

Efficient Storage Design

Vertical racking systems for hardwoods, sheet goods, clamps, and jigs help maximize limited floor space. Frequently used tools and materials are positioned within arm’s reach of the primary workstations to reduce search and setup time.

This layout keeps the shop organized, reduces downtime, and supports a steady build cadence throughout the week.

Safety & Compliance Plan

TimberForge also maintains certain safety measures that ensure that the shop is clean, compliant, and operational without any inconveniences. A special dust-collection system and periodic filter checks are ensured for dust control and ventilation. The milling, sanding, and finishing work involve hearing protection, eye protection, and respirators.

All big machines, such as the CNC router and table saw, are used in compliance with the safety guidelines of the manufacturer. An extra protection of the SawStop system is offered during the process of cutting, and the condition of guards, blades, and electrical parts is regularly checked.

Finishing materials are kept in approved, sealed containers, and oil-soaked rags are stored in metal bins to prevent ignition. The shop carries both general liability and product liability insurance, and all tasks follow OSHA guidelines for small woodworking shops, including rules for ventilation, fire safety, and equipment use.

Dust exposure and contact with machines are defined in OSHA as two of the most widespread shop hazards. So the dust-control and machine-guarding measures of TimberForge are of particular importance.

Technology Integration

TimberForge relies on a few utilitarian digital tools, which assist an owner with the design work, quoting, scheduling, and bookkeeping without introducing any additional complexity. It is aimed at stability and accuracy.

Design & CNC Workflow

The CAD software is used to develop 3D previews and produce CNC read files. This enhances the accuracy of the measurements, minimizes wastage of the material, and gives clients a clear visual of which cutting has started.

Project Tracking & Scheduling

Quotes, build notes, material requirements, and project schedules are stored in a basic job-management application or spreadsheet. This makes the owner stay in order, have lead time, and keep all the details of clients in a single place.

Inventory & Material Tracking

Hardwoods, sheet goods, and hardware are tracked in a simple digital log that is updated as projects progress. This helps the owner plan purchases, avoid shortages, and keep production running without delays.

Accounting & Financial Reporting

The invoicing, expenses, and end-of-year reports are handled using QuickBooks. A CPA goes through records once a month to provide clean financials to the lenders and proper tax filing.

Equipment Maintenance Records

The maintenance documentation of the CNC router, dust-collection system, and SawStop table saw is stored in a digital format. This maintains the organisation of service intervals and contributes to the long-term equipment reliability.

Does your plan sound generic and template-like

Refine your plan to adapt to investor/lender interests

Financial Plan

The financial plan outlines TimberForge’s startup funding, operating costs, and three-year forecast. The shop operates below break-even in Year 1 as it builds its client base and absorbs initial equipment costs.

With fixed monthly costs of about $7,500 and a break-even revenue level near $13,500 per month, the operation reaches its break-even point around Q2 of Year 2. From that point onward, improved workflow, recurring contractor work, and a part-time assistant support steady profitability through the remainder of Year 2 and Year 3.

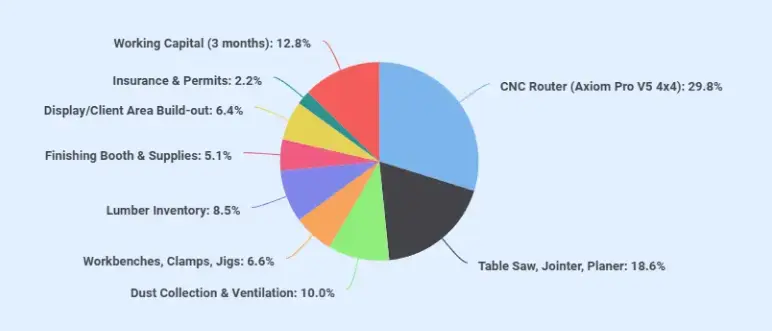

Startup Costs

TimberForge requires $104,000 to set up equipment, complete the shop build-out, and cover early operating needs.

| Category | Cost (USD) |

|---|---|

| CNC Router | 28,000 |

| Table Saw, Jointer, Planer | 17,500 |

| Dust Collection & Ventilation | 9,400 |

| Benches, Clamps, Jigs | 6,200 |

| Lumber Inventory | 8,000 |

| Finishing Booth & Supplies | 4,800 |

| Display/Client Area Setup | 6,000 |

| Insurance & Permits | 2,100 |

| Working Capital (3 months) | 12,000 |

| Total Startup Investment | 104,000 |

Remaining Capital:

Total Funding (110,000) – Startup Costs (104,000) = $6,000 opening cash balance.

Funding Structure

| Source | Amount (USD) | Notes |

|---|---|---|

| Equipment Loan | 68,000 | 5-year term, 8.9 percent fixed |

| Owner Equity | 42,000 | Savings + tool liquidation |

| Total Capital Available | 110,000 | Covers startup costs plus a small reserve |

Loan Terms (Proposed)

- Type: Small business equipment loan

- Lender: Rogue River Community Credit Union

- Amount: $68,000

- Term: 5 years

- Interest Rate: 8–9% (typical for equipment financing)

- Collateral: CNC router, SawStop table saw, jointer/planer, dust system

- Guarantee: Personal guarantee from the owner

This type of capital outfit provides the shop with adequate runway to finish the build-out and start production, as well as have dependable cash flow as it develops its customer base.

Important Assumptions

- Revenue mix: Custom builds, cabinetry, CNC jobs, installations, small-batch items

- Average ticket size: 1,200–3,800 for custom builds, 60/hr for CNC

- Material cost share: ~30 percent of revenue

- Operating expenses: Rent, utilities, insurance, consumables, software, marketing

- Owner compensation: Included within EBITDA margin assumptions

- Break-even point: ~13,500 per month

- Loan terms: 68,000 at 8.9 percent, 5 years

Revenue Forecasts

| Year | Revenue | Net Profit |

|---|---|---|

| Year 1 | 168,000 | –18,000 |

| Year 2 | 246,000 | 20,000 |

| Year 3 | 318,000 | 48,000 |

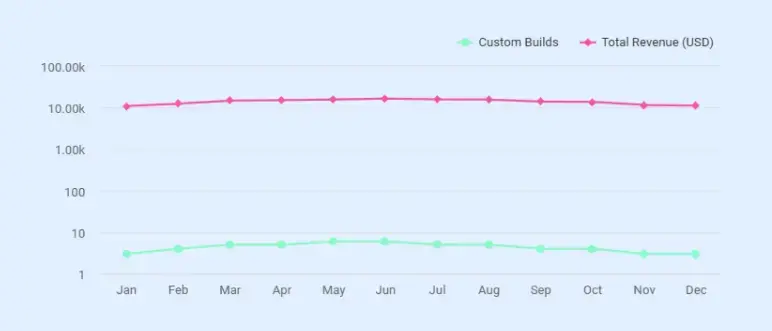

Monthly Projection (Year 1)

Assumes 4–6 medium custom projects per month, plus small CNC and product sales.

| Month | Custom Builds | CNC / Small Items | Total Revenue (USD) |

|---|---|---|---|

| Jan | 3 | Low | 11,000 |

| Feb | 4 | Low | 12,500 |

| Mar | 5 | Moderate | 14,800 |

| Apr | 5 | Moderate | 15,200 |

| May | 6 | Moderate | 15,800 |

| Jun | 6 | High | 16,500 |

| Jul | 5 | High | 15,900 |

| Aug | 5 | High | 15,700 |

| Sep | 4 | Moderate | 14,000 |

| Oct | 4 | Moderate | 13,800 |

| Nov | 3 | Low | 11,600 |

| Dec | 3 | Seasonal | 11,200 |

| Total Year 1 | — | — | 168,000 |

Projected Profit & Loss Statement (3 Years)

| Category | Year 1 ($) | Year 2 ($) | Year 3 ($) |

|---|---|---|---|

| Revenue | 168,000 | 246,000 | 318,000 |

| COGS (42%) | 70,560 | 103,320 | 133,560 |

| Gross Profit | 97,440 | 142,680 | 222,600 |

| Operating Expenses | |||

| Rent & Utilities | 24,000 | 25,200 | 26,400 |

| Marketing & Advertising | 6,000 | 7,200 | 8,400 |

| Insurance (Liability & Product) | 4,800 | 6,000 | 7,200 |

| Software Subscriptions | 3,600 | 3,900 | 4,200 |

| Bookkeeping & CPA | 3,000 | 2,400 | 2,400 |

| Repairs & Maintenance | 3,600 | 3,000 | 3,000 |

| Shop Supplies & Consumables | 4,800 | 6,000 | 7,200 |

| Owner Draw | — | 24,000 | 36,000 |

| Part-time Assistant | — | 12,000 | 18,000 |

| Miscellaneous / Admin | 3,600 | 4,200 | 5,000 |

| Total Operating Expenses | 53,400 | 93,900 | 117,800 |

| EBITDA | 44,040 | 48,780 | 66,640 |

| Depreciation | 10,300 | 10,300 | 10,300 |

| Interest Expense | 10,000 | 7,000 | 4,000 |

| Net Income Before Tax | 23,740 | 31,480 | 52,340 |

| Taxes (adjusted) | 0 | 11,480 | 4,340 |

| Net Income | –18,000 | 20,000 | 48,000 |

Projected Balance Sheet (3 Years)

| Category | Year 1 ($) | Year 2 ($) | Year 3 ($) |

|---|---|---|---|

| Assets | |||

| Cash & Cash Equivalents | 7,000 | 19,200 | 59,400 |

| Accounts Receivable | 5,000 | 6,500 | 8,000 |

| Inventory (lumber, hardware, etc.) | 8,000 | 9,000 | 10,000 |

| Prepaid Expenses | 1,200 | 1,200 | 1,200 |

| Total Current Assets | 21,200 | 35,900 | 78,600 |

| Property, Plant & Equipment (gross) | 72,700 | 75,700 | 78,700 |

| Less: Accumulated Depreciation | -10,300 | -20,600 | -30,900 |

| Fixed Assets (net) | 62,400 | 55,100 | 47,800 |

| Total Assets | 83,600 | 91,000 | 126,400 |

| Liabilities | |||

| Accounts Payable | 4,000 | 5,000 | 6,000 |

| Accrued Expenses | 2,400 | 2,800 | 3,200 |

| Current Portion of Equipment Loan | 13,600 | 13,600 | 13,600 |

| Total Current Liabilities | 20,000 | 21,400 | 22,800 |

| Long-Term Loan Balance | 54,400 | 40,800 | 27,200 |

| Total Liabilities | 74,400 | 62,200 | 50,000 |

| Owner’s Equity | |||

| Owner Investment | 42,000 | 42,000 | 42,000 |

| Retained Earnings | -18,000 | 22,800 | 50,000 |

| Total Equity | 24,000 | 44,000 | 92,000 |

| Total Liabilities & Equity | 98,400 | 106,200 | 142,000 |

Don’t waste time using spreadsheets

Projected Cash Flow (3 Years)

| Category | Year 1 ($) | Year 2 ($) | Year 3 ($) |

|---|---|---|---|

| Operating Activities | |||

| Net Income | –18,000 | 20,000 | 48,000 |

| Add: Depreciation | 10,300 | 10,300 | 10,300 |

| Change in Accounts Receivable | 5,000 | 1,500 | 1,500 |

| Change in Inventory | 8,000 | 1,000 | 1,000 |

| Change in Accounts Payable | 4,000 | 1,000 | 1,000 |

| Net Cash from Operations | –16,700 | 28,800 | 56,800 |

| Investing Activities | |||

| Equipment Purchases | –72,700 | –3,000 | –3,000 |

| Net Cash from Investing | –72,700 | –3,000 | –3,000 |

| Financing Activities | |||

| Credit Union Loan Proceeds | 68,000 | — | — |

| Loan Repayments | –13,600 | –13,600 | –13,600 |

| Owner Contributions | 42,000 | — | — |

| Net Cash from Financing | 96,400 | –13,600 | –13,600 |

| Net Cash Flow | 7,000 | 12,200 | 40,200 |

| Beginning Cash | 0 | 7,000 | 19,200 |

| Ending Cash Balance | 6,000 | 22,000 | 58,000 |

Break-Even Analysis

| Metric | Value |

|---|---|

| Average Ticket (blended) | $950 |

| Average Contribution Margin | 55% |

| Estimated Monthly Fixed Costs | $7,500 |

| Break-Even Revenue | ~$13,500 per month |

| Equivalent Production Volume | 2 medium builds + 8–10 CNC hours + a small batch of boards/trays |

| Break-Even Point Reached | Q2 of Year 2 |

Business Ratios

| Ratio | Year 1 | Year 2 | Year 3 |

|---|---|---|---|

| Gross Margin | 62% | 65% | 67% |

| Net Margin | -11% | 8% | 15% |

| Current Ratio | 1.6 | 1.9 | 2.4 |

| Quick Ratio | 1.2 | 1.6 | 2.1 |

| Debt-to-Equity | 0.67 | 0.51 | 0.34 |

| Return on Assets | -8% | 8% | 17% |

| Return on Equity | -13% | 12% | 23% |

The Quickest Way to turn a Business Idea into a Business Plan

Fill-in-the-blanks and automatic financials make it easy.